GENERAL DESCRIPTION

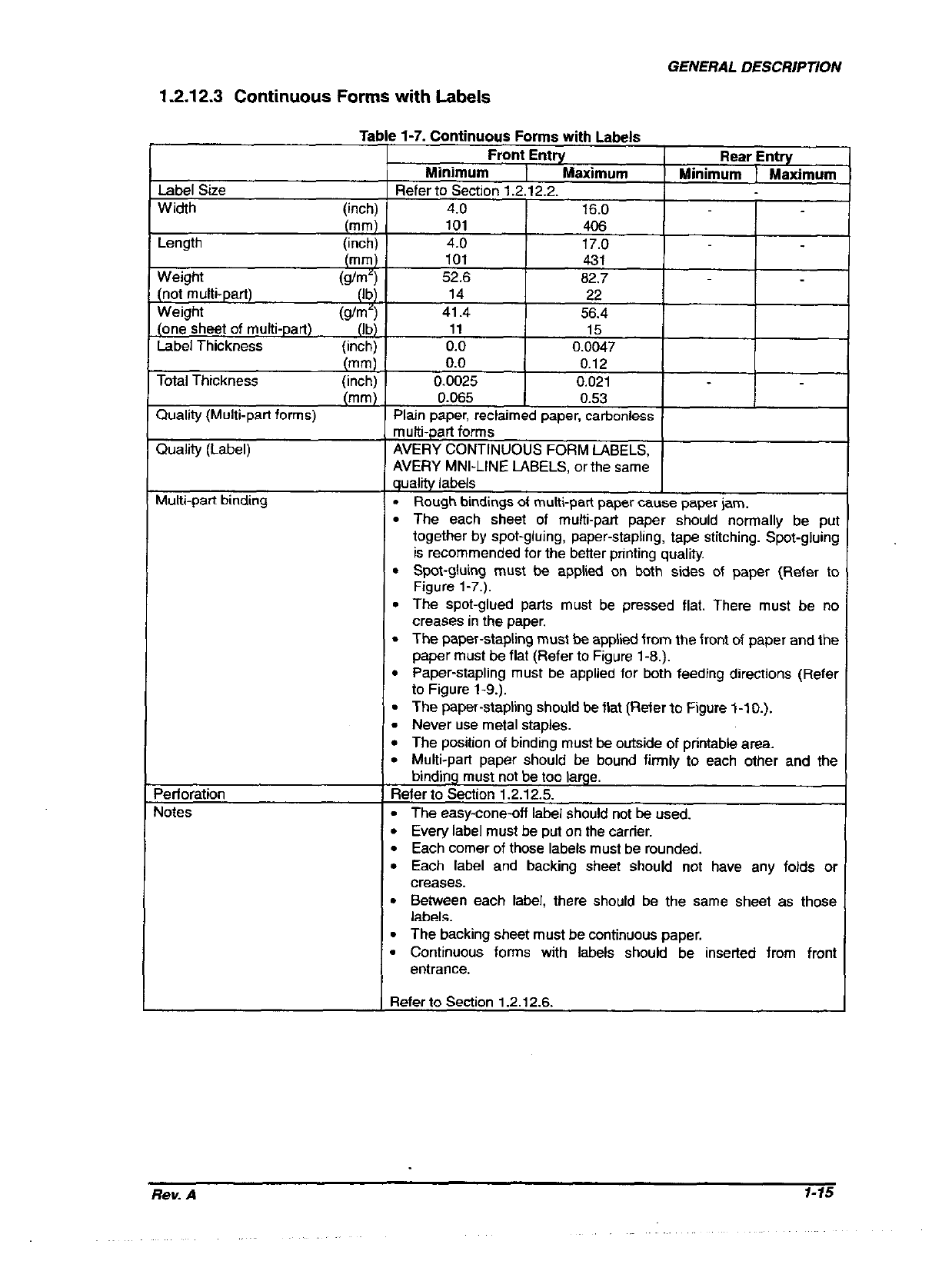

1.2.12.3 Continuous Forms with Labels

Label Size

Width

Length

JVeiqht

(inch]

(mm)

(inch]

:notmulti-part)

(

v&sight

;one sheet of multi-part)

(913

abel Thickness (inch)

(mm)

Total Thickness (inch)

(mm)

3uality (Multi-part forms)

3uality (Label)

&W-part binding

‘edoration

dotes

e 1-7. Continuous Forms with Labels

Front Entry

Rear Entry

Minimum

I

Maximum

Minimum 1 Maximum

Refer to Section 12.122.

4.0 I

Ifxl

I

11

15

0.0

0.0047

0.0

0.12

0.0025 0.021

0.065

0.53

Plain paper, reclaimed paper. carbonless

multi-part forms

AVERY CONTINUOUS FORM LABELS,

AVERY MNI-LINE LABELS, or the same

quality labels

I

Rough bindings ot multi-part paper cause paper jam.

.

.

.

.

.

.

.

.

.

.

The each sheet of multi-part paper should normally be pu

together by spot-gluing, paper-stapling, tape stitching. Spot-gluing

is recommended for the better pnnting quality

Spot-gluing must be applied on both sides of paper (Refer tc

Figure l-7.).

The spot-glued parts must be pressed flat. There must be nc

creases in the paper.

The paper-stapling must be applied from the front of paper and the

paper must be flat (Refer to Figure i-8.).

Paper-stapling must be applied for both feeding directions (Refer

to Figure l-9.).

The paper-stapling should be flat (R&r to Figure i-lo.).

Never use metal staples.

The position of binding must be outside of printable area.

Multi-part paper should bs bound firmly to each other and the

bmcknq must not be too large.

Refer to Section 1212.5.

The easy-cone-off label should not be used.

Every label must be put on the carrier.

Each comer of those labels must be rounded.

Each label and backing sheet should not have any folds or

creases.

Between each label, there should be the same sheet as those

labels.

The backing sheet must be continuous paper.

Continuous forms with labels should be inserted from front

entrance.

Refer to Section 1.2.12.6.

Rev. A

1-15