TROlJELESHOOTlAfG

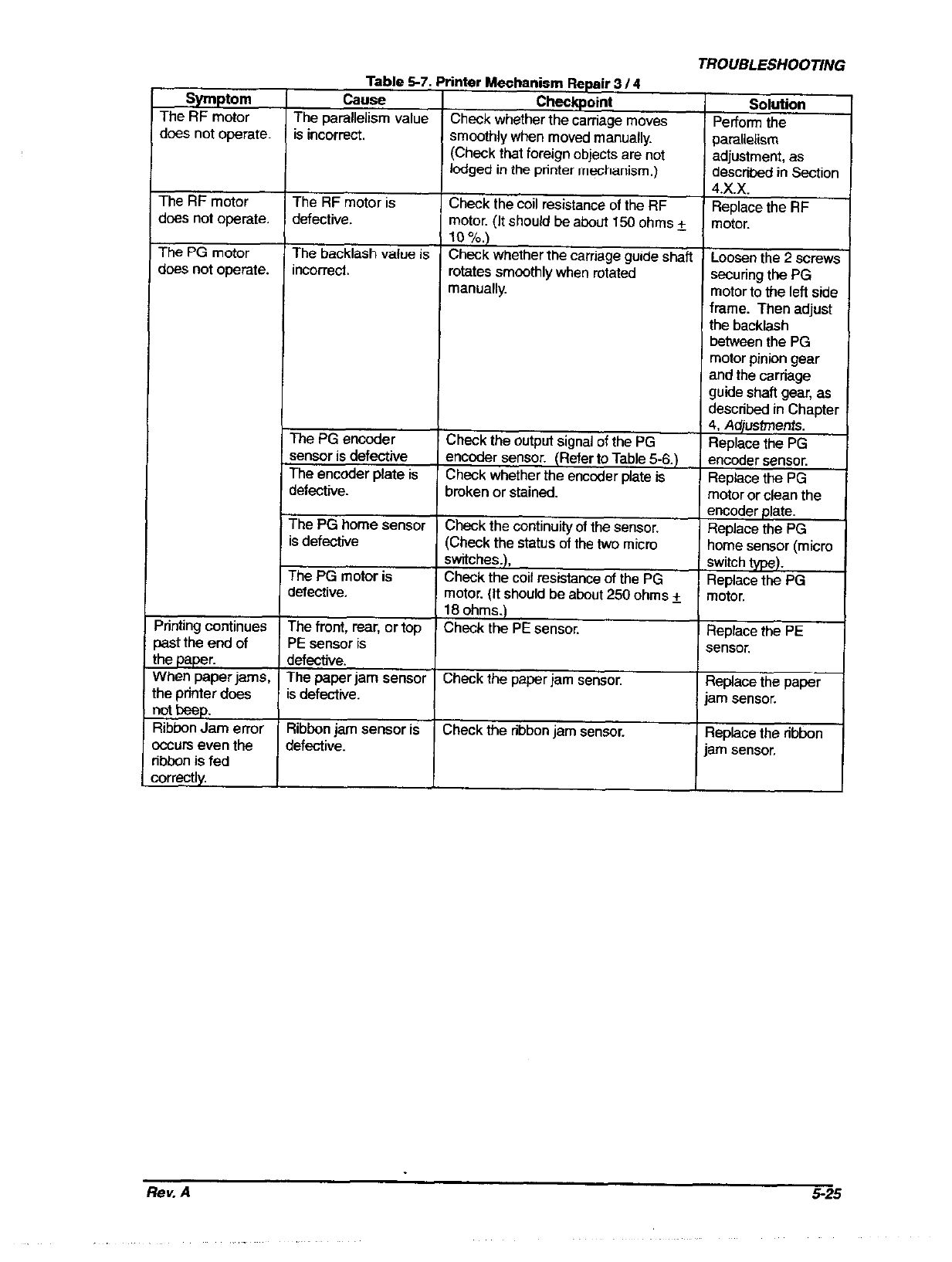

Table 57. Printer Mechanism Repair 3 I4

Symptom

I

cause

I

The RF motor

1 The parallelism value

Checkpoint

1 Check whether the carriaae moves

I

does not operate. 1 is incorrect.

1 smoothly when moved m&uall~

(Check that foreign objects arena

lodged in the printer mechanism.)

The RF motor

3oes not operate

The PG motor

joes not operate,

‘Ming continues

ast the end of

1e paper.

Vhen paper jams

,e printer does

ot beep.

libbon Jam error

cam even the

bbon is fed

3rrectly.

The RF motor is

Check the coil resistance of the RF

~ defective.

motor. (It should be about 150 ohms i

10 %.)

The backlash value is

incorrect.

Check whether the carriage guide shaft

rotates smoothly when rotated

manually.

le PG encoder

1 Check the outout sional of the

rl

~~=~~_~ _~ .~._ PG

sensor is defective

encoder sendr. (Refer to Table 5-6.)

The encoder plate is 1 Check whether the encoder plate is

defective.

broken or stained

The PG home sensor

is defective

Check the continuity of the sensor.

(Check the status of the two micro

witches.),

The PG motor is

Check the coil resistance of the PG

defective.

motor. (It should be about 260 ohms +

18 ohms.)

The front, rear, or top

Check the PE sensor.

PE sensor is

defective.

The paper jam sensor Check the paper jam sensor.

is defective.

Ribbon jam sensor is

Check the ribbon jam sensor.

defective.

Solutiin

Perform the

paralleliim

adjustment, as

described in Section

4.x.x.

Replace the RF

Loosen the 2 screw

securing the PG

motor to the left side

frame. Then adjust

:he backlash

3etween the PG

notor pinion gear

3rd the carriage

guide shaft gear, as

lesctibed in Char&

t, Adjustments.

3eplace the PG

?ncoder sensor.

3eplace the PG

notor or clean the

?ncoder plate.

3eplace the PG

wne sensor (micro

witch

)

3eplace the.PG

notor,

Replace the PE

iensor.

leplace the paper

un sensor.

lep!=ace the ribbon

*m sensor.

Rev. A

5-25