MJ-1103/1104 © 2008, 2009 TOSHIBA TEC CORPORATION All rights reserved

ADJUSTMENTS

5 - 2

(5) Press the [Button1] to adjust the alignment position.

Every time the [Button1] is pressed, the alignment plate shifts 1 step (0.419 mm/step) toward the

“+ “direction. (The gap between the alignment plates becomes narrower.)

Adjustment range is from -5 to +5 steps.

If the [Button1] is pressed when the alignment position is at the “+5 step”, the plate will return to

the home position and then moves to the position of “-5 step”.

Fig. 5-2

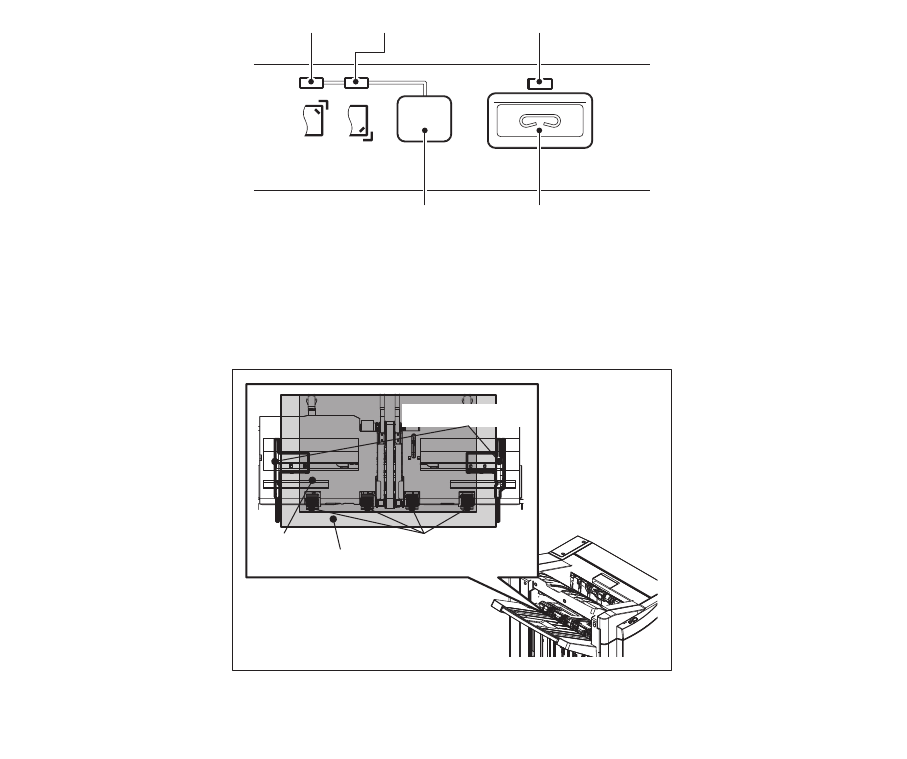

(6) Place the adjustment sheet on the process tray and adjust the position to make the gap between

paper and the alignment plate “0”.

Then setting is performed at a value that is one smaller than the adjustment value.

Fig. 5-3

Remarks:

• Use an adjustment sheet made of plastic resin which is light and accurate in measurement

(e.g. OHP film).

• To reduce frictional resistance with the vertical alignment roller on the process tray, place a

sheet of B5 paper beneath the adjustment sheet on the vertical alignment roller.

• Confirm the gap between paper and the alignment plate by moving the adjustment sheet for-

ward and backward to reduce affect by backrush of the gear of the side alignment plate.

LED3 LED2 LED1

Button2Button1

Adjustment sheet

Vertical

alignment roller

B5 paper

alignment plate