E6581381

E-25

5

[Parameter setting]

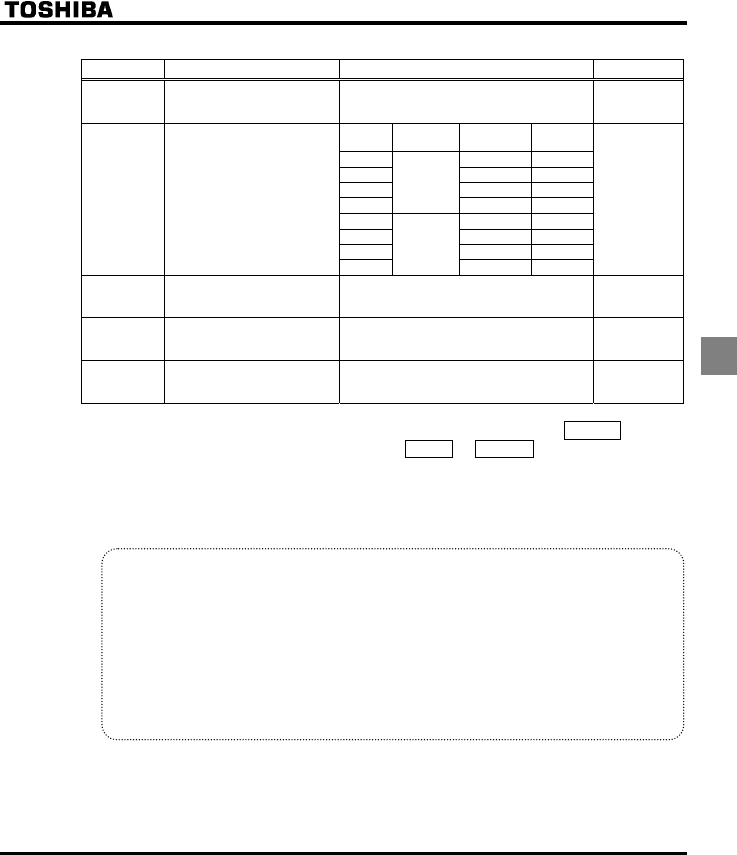

Title Function Adjustment range Default setting

VJT

Motor electronic thermal

protection level 1

10 – 100 (%) / (A) 100

Setting

value

Overload

protection

Overload

stall

0

{

×

1

{{

2

××

3

Standard

motor

×

{

4

{

×

5

{{

6

××

QNO

Electronic-thermal protection

characteristic selection

7

VF motor

(special

motor)

×

{

{

H

Motor electronic-thermal

protection level 2

10 – 100 (%) / (A) 100

H

Motor 150%-overload time

limit

10 – 2400 (s) 300

H

Thermal memory selection

0: Disabled

1: Enabled

0

* { : valid, × : invalid

1) Setting the electronic thermal protection characteristics selection QNO and

motor electronic thermal protection level 1 VJT

, 2 H

The electronic thermal protection characteristics selection QNO is used to enable or disable the motor

overload trip function (QN) and the overload stall function.

While the inverter overload trip (QN) will be in constant detect operation, the motor overload trip (QN)

can be selected using the parameter QNO

Explanation of terms

Overload stall: This is an optimum function for equipment such as fans, pumps and blowers with

variable torque characteristics that the load current decreases as the operating speed

decreases.

When the inverter detects an overload, this function automatically lowers the output

frequency before the motor overload trip QN is activated. This function operates a

motor at frequencies that allow the load current to keep its balance so that the

inverter can continue operation without being tripped.

Note: Do not use the overload stall function with loads having constant torque characteristics (such as

conveyor belts in which load current is fixed with no relation to speed).

[Using standard motors (other than motors intended for use with inverters)]

When a motor is used in the lower frequency range than the rated frequency, that will decrease the cooling

effects for the motor. This speeds up the start of overload detection operations when a standard motor is

used in order to prevent overheating.