4 - 33

Connect Power

Power options include:

• 12-48 VDC Vehicles (10-60 VDC Direct Connection) (see page 4-34) - Direct connection to vehicle power.

• 60-144 VDC Vehicles (50-150 VDC Power Supply, Screws on Side of Lid) (see page 4-39) - Requires the use of a DC/

DC power supply.

• 60-144 VDC Vehicles (50-150 VDC Power Supply, Screws on Top of Lid) (see page 4-43) - Requires the use of a DC/

DC power supply.

• VX6 / VX7 Adapter Cable (see page 4-47) - For applications where the Thor VM2 replaces a previously installed VX6 or

VX7.

• Thor VX8 / Thor VX9 Adapter Cable (see page 4-48) - For applications where the Thor VM2 replaces a previously

installed Thor VX8 or Thor VX9.

• Screen Blanking (see page 4-49) - Optional connection to blank the Thor VM2 display while the vehicle is in motion.

• External AC/DC Power Supply (see page 4-52) - For use when DC power is not available to power the Thor VM2, such

as in an office environment.

See Power Supply Connector (page 10-4) for connector pinout

Power Cable Cautions

Power Cable Routing

CAUTION - When routing the power cable:

• Route power cable away from the outside of the fork truck.

• Choose a mounting location so that the power cable does not extend outside the vehicle and that provides sufficient

clearance so that the power cable (especially the dock connector end) is not pressed against part of the vehicle.

• Use the proper Strain Relief Cable Clamps (page 4-32) to secure cable.

• The power cable is less flexible in low temperature environments. Avoid sharp bends.

Regularly inspect power cable for damage, especially in low temperature environments. Contact Technical

Assistance (page 11-1) for replacement cable options.

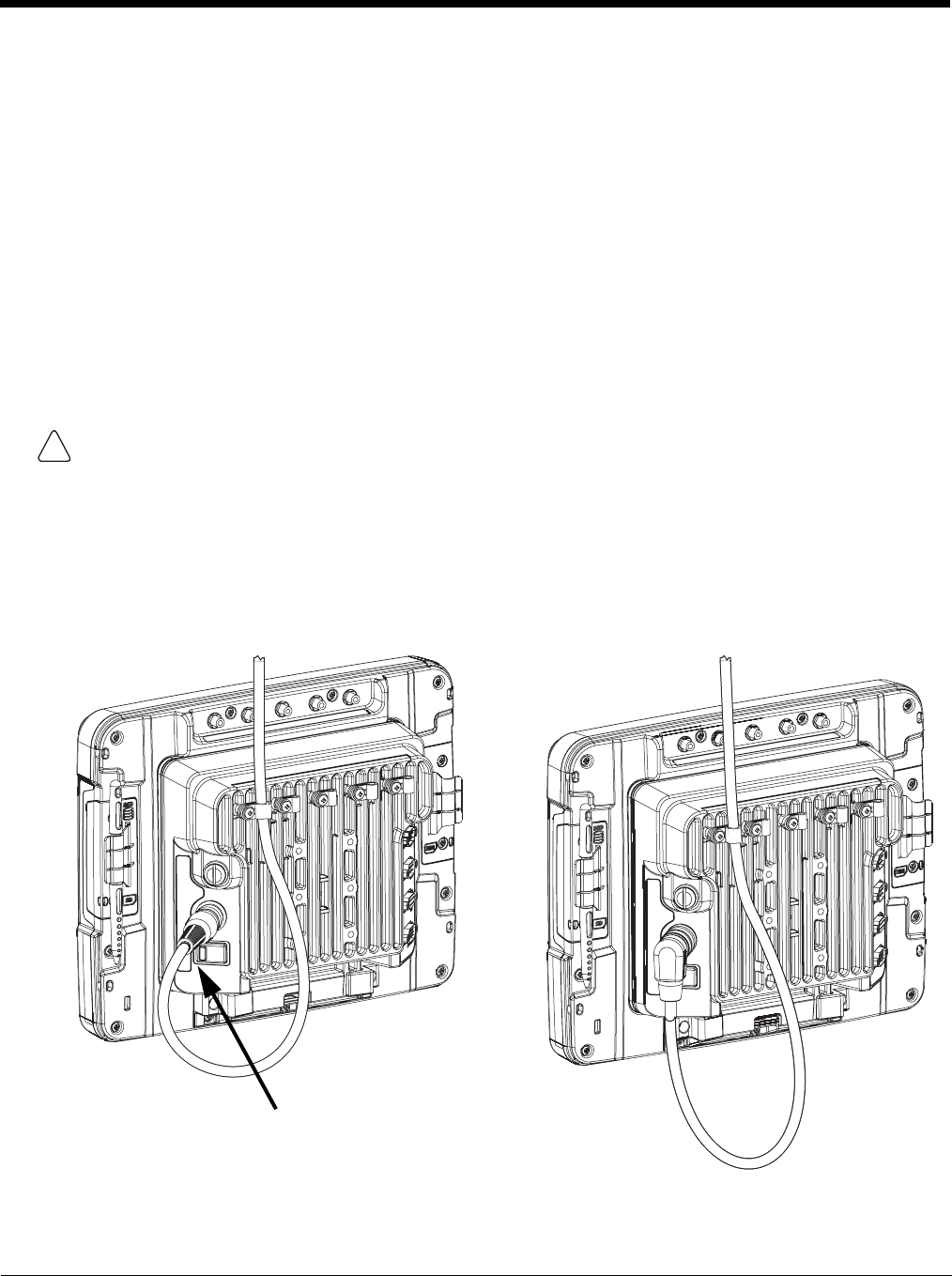

Power cable with straight connector Power cable with right-angle connector

!

Avoid sharp bends in this

area of the power cable