9 - 2

9.2 Maintenance

To keep programmable controllers in the best operating condition, conduct the

following daily inspection and periodic inspection.

(1) Daily inspection

The following table lists the items that must be inspected daily.

Table 9.1 Daily inspection

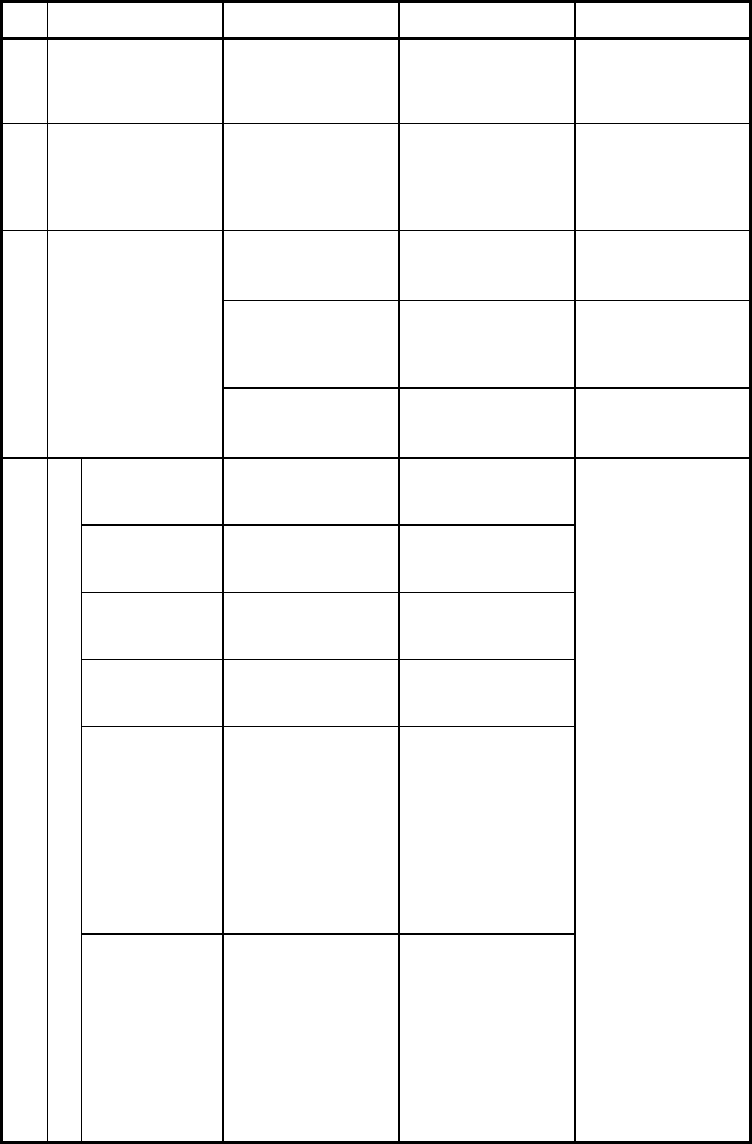

Item Inspection item Inspection contents Judgment criterion Measures

1

Installation of base

unit

Check that fixing

screws are not loose

and the cover is not

dislocated.

The screws and

cover must be

installed securely.

Retighten the

screws.

2

Installation of I/O

module

Check that the

module is not

dislocated and the

module fixing hook is

engaged securely.

The module fixing

hook must be

engaged and

installed securely.

Securely engage the

module fixing hook.

Or tighten the screw.

Check for loosening

of the terminal

screws.

Screws must not be

loose.

Retighten the

terminal screws.

Check for the

distance between

solderless terminals.

The proper distance

must be provided

between solderless

terminals.

Set the proper

distance.

3

Connection

conditions

Check the connector

part of the cable.

Connectors must not

be loose.

Retighten the

connector fixing

screws.

Power supply

module

"POWER" LED

Check that the LED

is on.

The LED must be on.

(Error if the LED is

off)

CPU "RUN" LED

Check that the LED

is on in RUN status.

The LED must be on.

(Error if the LED is

off)

CPU "ERROR"

LED

Check that the LED

is off.

The LED must be off.

(Error if the LED is

on or flashing)

CPU "BAT.ARM"

LED

Check that the LED

is off.

The LED must be off.

(Error if the LED is

on)

Input LED

Check that the LED

turns on and off.

The LED must be on

when the input power

is turned on.

The LED must be off

when the input power

is turned off.

(Error if the LED

does not turn on or

turn off as indicated

above)

4

Module indication LED

Output LED

Check that the LED

turns on and off.

The LED must be on

when the output

power is turned on.

The LED must be off

when the output

power is turned off.

(Error if the LED

does not turn on or

turn off as indicated

above)

Refer to QCPU (Q

mode) User's

Manual.