9 - 3

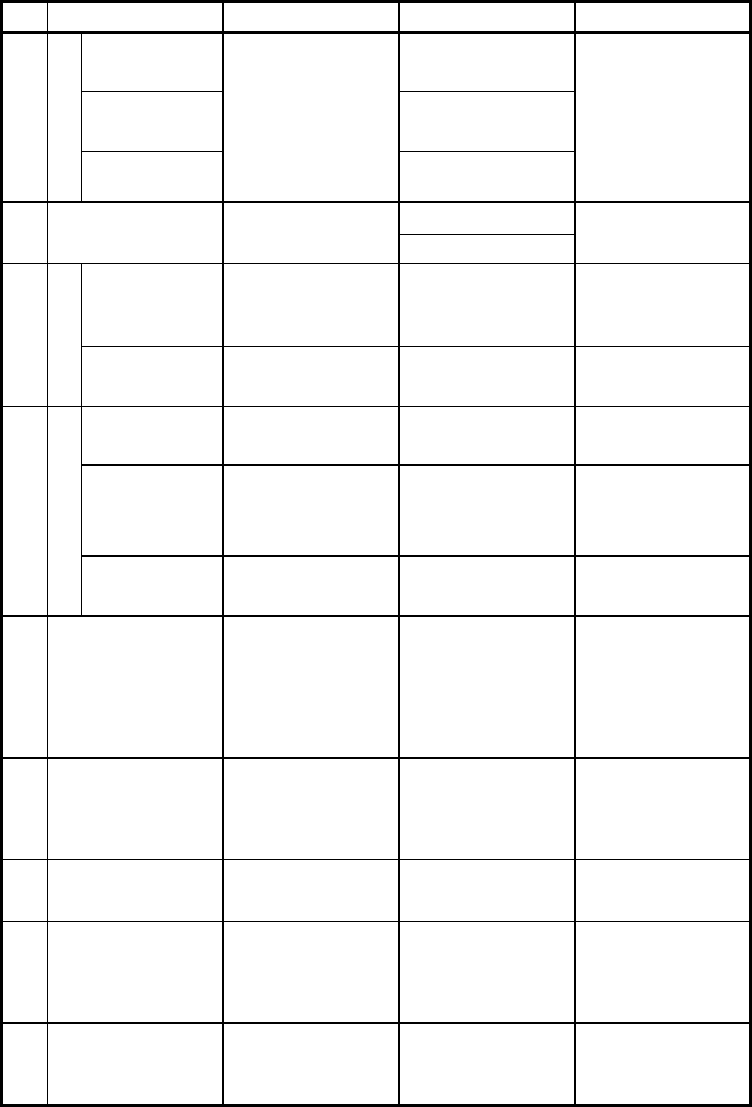

(2) Periodic inspection

The following table lists the items that must be inspected one or two times every

half year to a year. When the equipment has been relocated or modified, or

wiring layout has been changed, perform this inspection.

Table 9.2 Periodic inspection

Item Inspection item Inspection contents Judgment criterion Measures

Ambient

temperature

0 to 55 °C

Ambient humidity 5 to 95% RH

*1

1

Ambient environment

Ambience

Measure the

temperature and

humidity with a

thermometer and a

hygrometer.

Measure corrosive gas.

Corrosive gas must not

be present.

When the

programmable

controller is used in the

board, the ambient

humidity in the board is

the ambient humidity.

85 to 132VAC

2

Power supply voltage

Measure the voltage

across the terminals of

100/200VAC.

170 to 264VAC

Change the power

supply.

Looseness, rattling

Move the module to

check for looseness and

rattling.

The module must be

installed securely.

Retighten the screws.

If the CPU, I/O, or

power supply module is

loose, fix it with screws.

3

Installation

Adhesion of dirt

and foreign matter

Check visually.

Dirt and foreign matter

must not be present.

Remove and clean the

dirt and foreign matter.

Looseness of

terminal screws

Retighten screws with a

screwdriver.

Screws must not be

loose.

Retighten the terminal

screws.

Distance between

solderless

terminals

Check visually.

The proper distance

must be provided

between solderless

terminals.

Set the proper distance.

4

Connection conditions

Looseness of

connectors

Check visually.

Connectors must not be

loose.

Retighten the connector

fixing screws.

5

Battery

Check that SM51 or

SM52 is turned off with

GX Works2.

(Preventive

maintenance)

Even if the lowering of a

battery capacity is not

displayed, replace the

battery with a new one i

f

the specified service life

of the battery is

exceeded.

6

Spare product

Install the product on

the actual

programmable

controller and check the

operation.

The operation must

meet the specifications.

Use the normal product

on the actual

programmable

controller as a spare

product.

7

Check the stored

program

Compare the stored

program with the

running program.

The two programs must

be identical.

Correct if any difference

is found.

8

Fan (heat exchanger)

filter

Rotation status

Rotation sound

Clogging

The fan must rotate

without abnormal

sounds.

The fan must rotate

without clogging.

Replace if any error is

found.

Clean.

9

Analog I/O

Check the offset/gain

value.

The value must be

identical with the

specifications (design

value).

Correct if any difference

is found.

*1: When AnS Series Module is used in the system, the judgment criteria will be from 10 to 90% RH.

9.3 Consumable Product

Backup batteries on programmable controllers are consumable products.