App. - 24

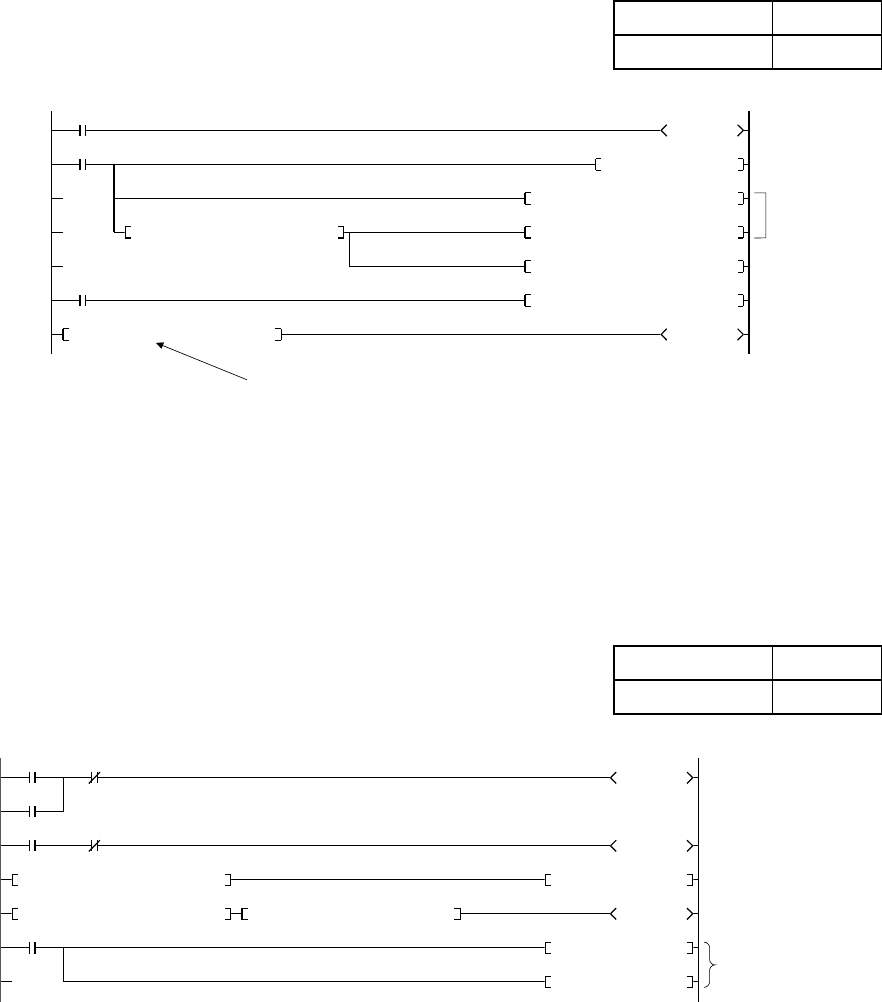

Appendix 4.16 Measuring operation time

Setting an operation time to a control target is useful for judging the timing of a

component replacement and lubrication. The timer ST and data register D must

have a backup power source so that they can continue operating at a power failure.

With the contents of D31 (in one hour units) displayed externally, the program can

work as an operation timer.

Project name QA-23

Program name MAIN

ST250

X2

ST250

0

5

Measures in

1 hour units

6-minute timer

Indicates timing

to replace

K3600

D30K0MOV

ST250RST

D30K1+

D31K1+

K4Y60D31BCD

D30K10=

SM400 (always ON)

21

D31K1000<=

25

Y70

1-hour timer

Outputs operation

time to exterior

The management time is set to 100 hours.

Appendix 4.17 Measuring cycle time

Measuring the operation time of a control target (from its start to end) allows

displaying the cycle time-out and managing a control time lag.

The following ladder in which the <, >, and = instructions are used to determine the

state of T200 indicates a cycle time-out and measures a time lag with the counter.

Project name

QA-24

Program name MAIN

M56

X0

M56

0

4

Measures cycle time

In cycle

X1

M56

T200

X7

24

T200

K32760

Y70SET

10

T200K400<

14

T200K300< T200K400>= C10

K32760

Y70RST

C10RST

Cycle time run out

Number of cycle times

of 3.01 to 4.00sec.

Clears time out display

and accumulated counts