Phaser 84000/8500/8550/8560 Color Printer Service Manual 6-9

Adjustments and Calibrations

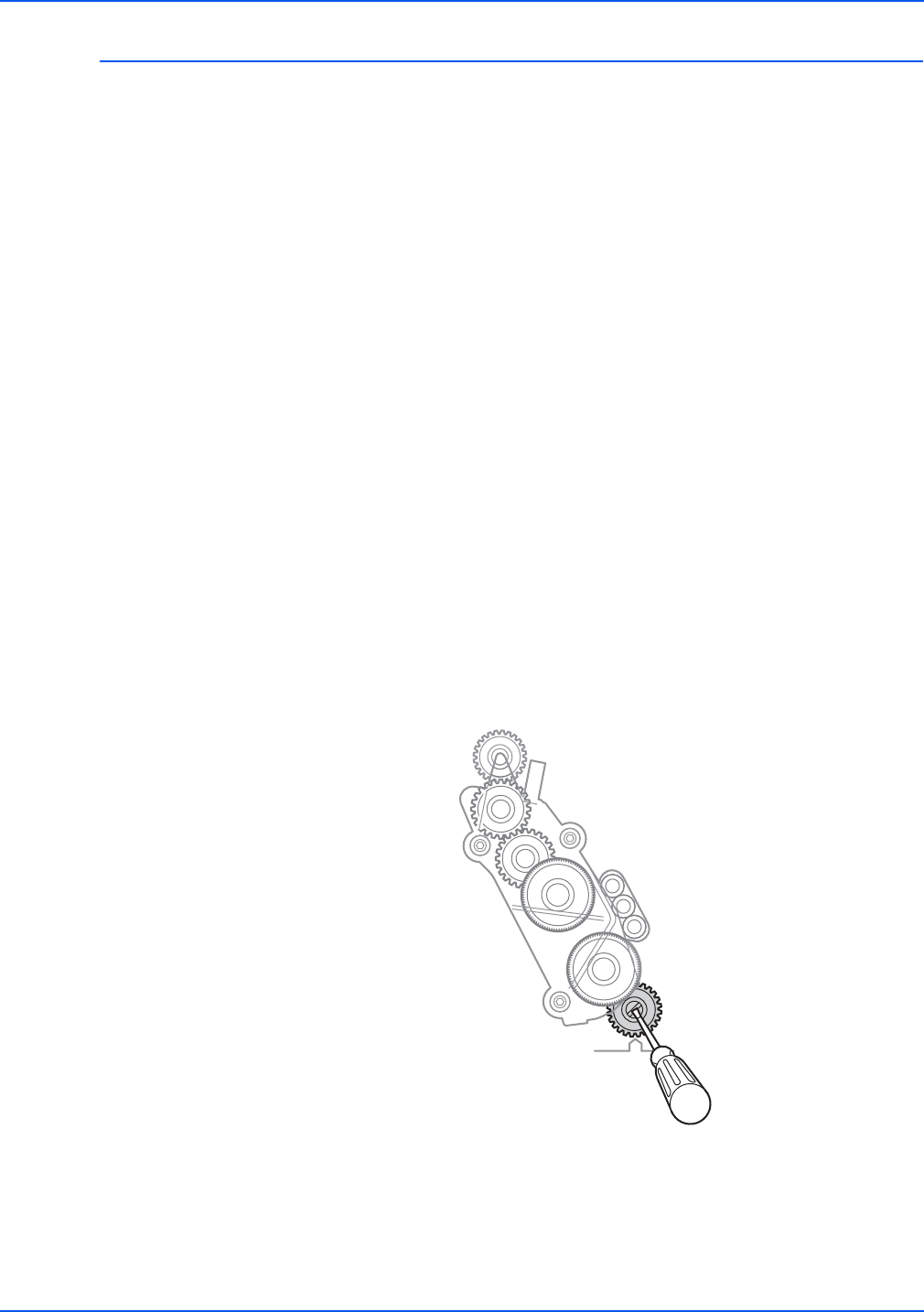

Timing the Drum Maintenance Camshaft

Caution

Use either the pins that come with replacement Process Drives, or a

paper clip, bent into a U shape to hold the gears in their proper position

during removal and replacement. If the Process Drive is incorrectly

installed, the printer could be damaged. See “Homing the Process Drive

Train” on page 6-8

.

The Process Drive screws are torqued to 12 in. lbs. Irreversible damage

to the chassis mounting bosses or the threads can result if screws are

over tightened.

After replacing the Process Drive, Drum Maintenance Pivot Plate or the Drum

Maintenance Camshaft (or any component requiring removal of the Process

Drive), the printer may experience Front Cover jams from Tray

2. The jam

occurs with paper in the Preheater and C3T jam errors (strip flag timeout

during transfix) recorded in Jam History. In many cases, Tray 1 (MPT) prints

with no jams.

These symptoms indicate that the Transfix Load Module is incorrectly timed

resulting in a late arrival of the leading edge at the strip flag. The likely cause

is the position of the Drum Maintenance Camshaft gear in relation to the

Process Drive gear. To correct the timing problem requires removal of the

Process Drive and realignment of the Drum Maintenance Camshaft.

To correct the problem, follow these steps:

1. Using a flat-blade screwdriver, rotate the Drum Maintenance Camshaft

clockwise to tilt the Printhead forward to its home position. This

disengages the Printhead and Head Tilt Gear from the Drum

Maintenance Camshaft.

2. Pin the Process Drive gears using a paper clip or similar object to keep

the gear set in its disengaged orientation during removal and

replacement.

3. Remove the Process Drive (page 8-43).

s8560-198