6 – 3

Chapter 6 Principles of Operation

1.3 Description of Printing Process Techniques

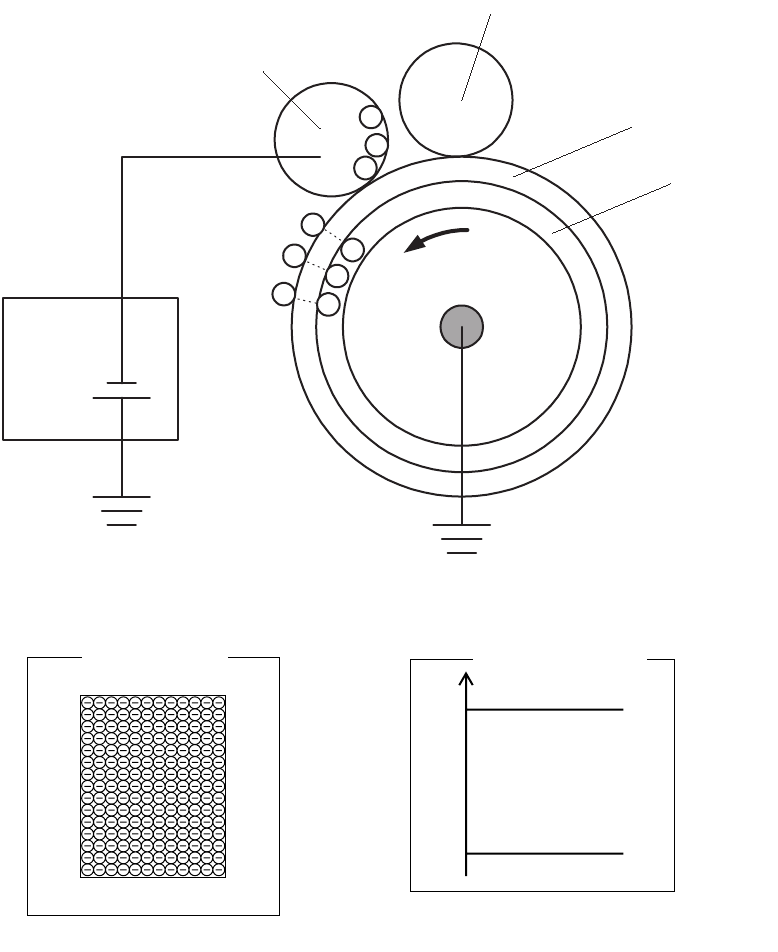

1.3.1 Charging with electricity

In the charging process, the drum surface rotating at a constant speed is charged uniformly with

negative electricity by discharging of RTC (Rubber Tube Charge: Charged film).

This process is performed in parallel for yellow, magenta, cyan and black colors.

- The RTC is kept in contact with the drum and rotates following the rotations of the drum.

RTC is a conductive roll, receives discharge voltage from HIGH VOLTAGE POWER SUPPLY

(HVPS) and discharges at minus DC voltage.

- The drum surface is uniformly and negatively charged with DC bias voltage.

The drum surface is optical conductor (which is insulator in a dark place and conductor when

receiving light) and the drum inside is composed of conductor.

- The Refresher is a conductive brush, and it receives negative DC voltage from the HIGH

VOLTAGE POWER SUPPLY (HVPS) to catch the toner of reverse polarity returned to the drum via

IDT. Also, it removes discharge products.

-

+

-

-

+

+

-

-

-

RTC

Refresher

HVPS

Photoreceptor

Conductor

Ten06039KA

Drum

Drum surface

engine principle0005FA

Electric potential

on drum

-V

0

engine principle0006FA