e-STUDIO281c/351c/451c PREVENTIVE MAINTENANCE (PM) June 2005 © TOSHIBA TEC

4 - 12

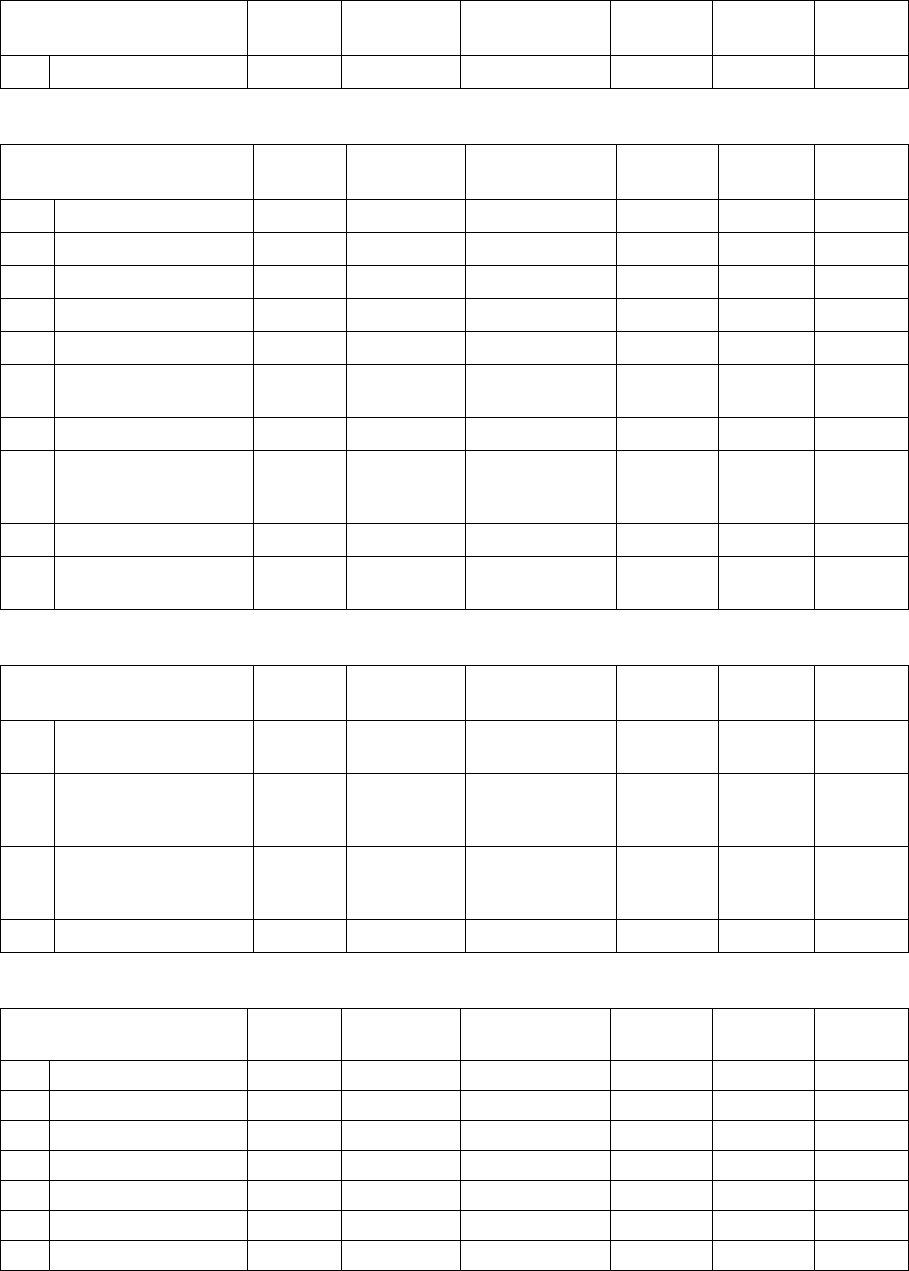

B. Laser unit

C. Feed unit

D. Automatic duplexing unit

E. Bypass feed unit

Items to check Cleaning

Lubrication/

Coating

Replacement

(KS)

Operation

check

Parts list

<P-I>

Remarks

B1 LSU slit glass B

Items to check Cleaning

Lubrication/

Coating

Replacement

(KS)

Operation

check

Parts list

<P-I>

Remarks

C1 Pickup roller 80 18-20

C2 Feed roller 80 18-24

C3 Separation roller AV, W2 80 18-5 *c1

C4 Transport roller A R

C5 Paper guide B

C6 Drive gear

(tooth face and shaft)

W1 *c2

C7 GCB bushing bearing L

C8 One side of the plastic

bushing to which the

shaft is inserted

W1

C9 Registration roller A R 23-15,34

C10 Paper dust removal

brush

B R 23-2,30 *c10

Items to check Cleaning

Lubrication/

Coating

Replacement

(KS)

Operation

check

Parts list

<P-I>

Remarks

D1 Transport roller (upper,

middle and lower)

AR43-7,

36,56

D2 One side of the GCB

bushing to which the

shaft is inserted

L

D3 One side of the plastic

bushing to which the

shaft is inserted

W1

D4 Paper guide B 43-46

Items to check Cleaning

Lubrication/

Coating

Replacement

(KS)

Operation

check

Parts list

<P-I>

Remarks

E1 Pickup roller 80 22-26

E2 Feed roller 80 22-37

E3 Separation roller AV, W2 80 21-1 *e1

E4 Bypass tray B

E5 Drive gear (shaft) W1

E6 GCB bushing bearing L

E7 Transport roller A R 22-4,40

05/07