5. SYSTEM MODE EO18-33027

5.3 SELF-DIAGNOSTIC TEST

5-7

When the power is off, a drive time of 27 seconds or less is rounded down and backed up.

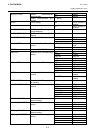

232C ERR RS-232C hardware error count

0 255

Counts when a parity error or a framing error occurs.

* When data of several bytes is transmitted continuously, counting is performed per byte.

SYSTEM ERR System error count

0 15

Counts when a system error occurs.

POWER FAIL Momentary power interruption count

0 15

Counts when a momentary power interruption occurs.

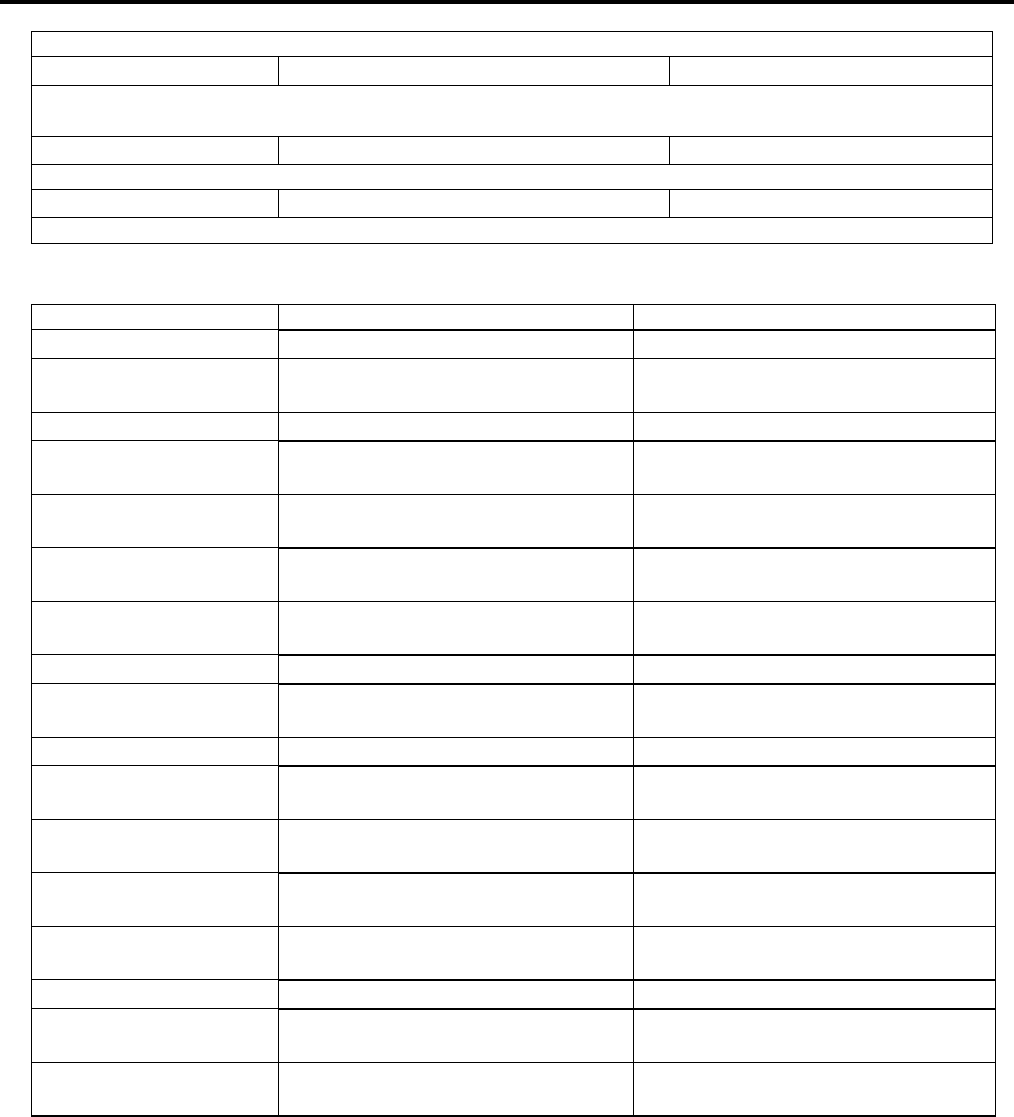

<< ADJUST >>

Item Content Remark

[PC]FEED Feed fine adjustment

-50.0mm +50.0mm (*1)

CUT

Cut position (or strip position) fine

adjustment

-50.0mm +50.0mm (*1)

BACK

Back feed fine adjustment

-9.9mm +9.9mm (*1)

TONE(T)

Print density fine adjustment

(Thermal transfer print mode)

-10 +10step

TONE(D)

Print density fine adjustment

(Direct thermal print mode)

-10 +10step

RBN(FW)

Ribbon motor drive voltage fine

adjustment (Rewind)

-15 +10step

RBN(BK)

Ribbon motor drive voltage fine

adjustment (Back tension)

-15 +10step

[KEY]FEED

Feed fine adjustment

-50.0mm +50.0mm

CUT

Cut position (or strip position) fine

adjustment

-50.0mm +50.0mm

BACK

Back feed fine adjustment

-9.5mm +9.5mm

TONE(T)

Print density fine adjustment

(Thermal transfer print mode)

-20 +10step

TONE(D)

Print density fine adjustment

(Direct thermal print mode)

-20 +10step

RBN(FW)

Ribbon motor drive voltage fine

adjustment (Rewind)

-15 +10step

RBN(BK)

Ribbon motor drive voltage fine

adjustment (Back tension)

-15 +10step

X ADJ.

X-coordinate fine adjustment

-99.5mm +99.5mm

THRESHOLD<R>

Reflective sensor manual threshold

fine adjustment

0.0V 4.0V

THRESHOLD<T>

Transmissive sensor manual

threshold fine adjustment

0.0V 4.0V

NOTES: For B-EX4T1-G, “x.3mm” is printed as maintenance counter regardless the selection “x.2 mm” or

“x.3mm” since head resolution is 8 dots/mm. The selection of “x.7mm” and “x.8mm” is same manner.