E6580757

M-6

13

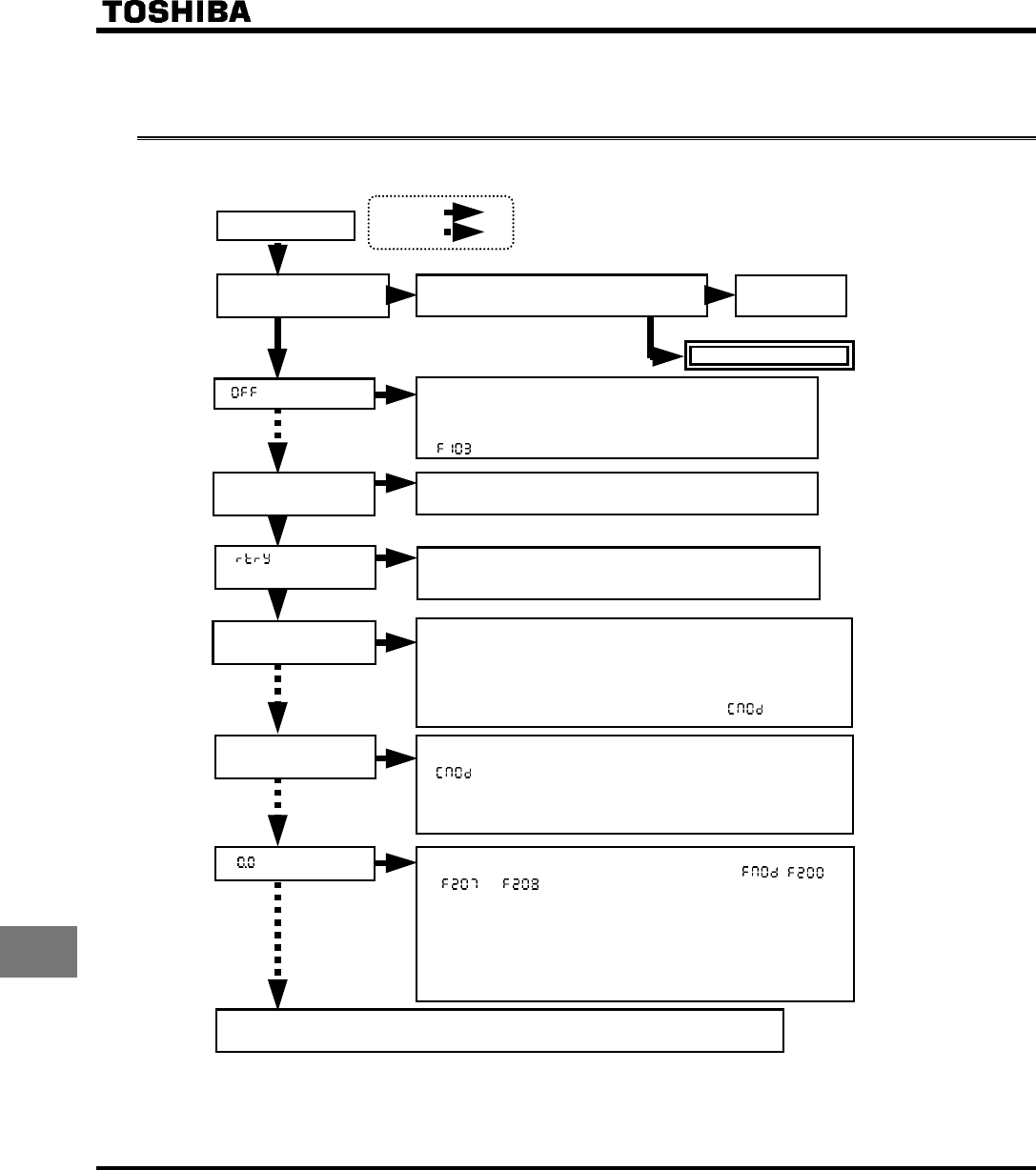

13.3 If the motor does not run while no trip message is

displayed ...

If the motor does not run while no trip message is displayed, follow these steps to track down the cause.

Check the power supply and the MCCB.

Is power being supplied normally?

The motor does not run.

Is the 7-segment LED

extinguished?

Make a service call.

Supply the power

normally.

Is displayed?

• The ST-CC circuit is opened. Close the circuit between CC and the terminal

to which the ST (standby) function on the control circuit terminal is assigned.

(See 6.3.2.)

• Properly change the setting of the ST (standby) signal selection parameter

. (See 6.2.1.)

Track down and eliminate the cause of the failure and then reset the inverter.

See 13.2.

Is any failure message

displayed? (See 13.1.)

Are and a failure message

displayed alternately?

Is the LED of the RUN/STOP

key lighted?

Is the LED of the RUN/STOP

key off?

The inverter is in the process of retrying. The retry function can be disabled by

normal or emergency stop operation, or by turning off the inverter.

Is : displayed?

• When operation panel operation is selected ...

Press the RUN key to start the operation.

• Check whether the operation panel operation frequency is set properly. (See 3.2.2.)

• When another control mode is selected ...

Change the setting of the operation control mode selection . (See 3.2.1.)

• When operation panel operation is selected ...

Change the setting of the operation control mode selection parameter

to 1. (See 5.5.)

• You can check the setting of each input terminal on the monitor. (See 8.1.)

• When another control mode is selected ...

Check whether the external operation command is entered.

• Check to see that the frequency setting signal is not set at zero.

• Check the settings of the frequency setting signal parameters , ,

and . (See 6.5.)

• Check the frequency setting signal points 1 and 2 settings. (See 6.5.)

• Check that the start-up frequency is not higher than the operation frequency. (See

6.6.)

• Check that the frequency setting (preset-speed operation frequency, etc.) is not set

at zero.

• Check that the motor is not under a too large load or not locked up. -> Reduce the

load if necessary.

Determine the cause, using the parameter display function and the status monitoring function.

Refer to Section 11 for the parameter display function or Section 8 for the status motoring function.

YES :

NO

: