E6580757

E-3

5

✩ If the programmed value is shorter than the optimum acceleration/deceleration time determined by load

conditions, overcurrent stall or overvoltage stall function may make the acceleration/deceleration time

longer than the programmed time. If an even shorter acceleration/deceleration time is programmed, there

may be an overcurrent trip or overvoltage trip for inverter protection. (for further details, see 13.1).

5.2 Increasing starting torque

: Automatic torque boost

• Function

Simultaneously switches inverter output (V/F) control and programs motor constants automatically (On-

line automatic-tuning function) to improve torque generated by the motor. This parameter integrates the

setting of special V/F control selection such as vector control.

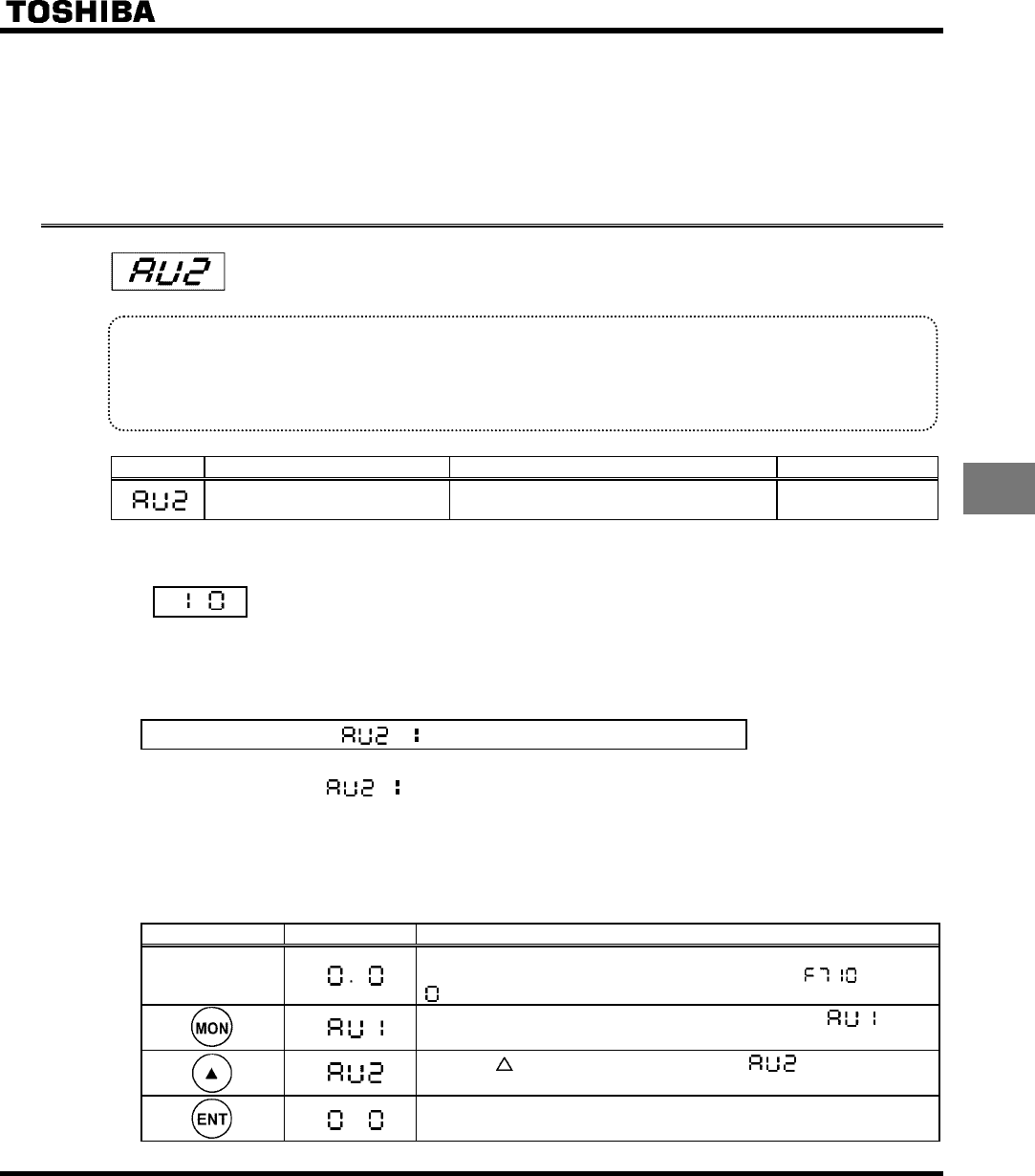

Title Function Adjustment range Default setting

Automatic torque boost

0: Disabled

1: Sensorless vector control + auto-tuning

0

Note:Parameter displays on the right always return to 0 after setting. The pervious setting is displayed on the left.

Ex.

1) When using vector control (increasing starting torque and high-precision opera-

tions)

Set the automatic control to (sensorless vector control + auto-tuning)

Setting automatic control to (sensorless vector control + auto-tuning) provides high starting torque

bringing out the maximum in motor characteristics from the low-speed range. This suppresses changes in

motor speed caused by fluctuations in load to provide high precision operation. This is an optimum feature for

elevators and other load transporting machinery.

[Methods of setting]

Key operated LED display Operation

Displays the operation frequency. (Perform during operation

stopped.) (When standard monitor display selection is set to

[operation frequency])

Press the MON key to display the first basic parameter

(automatic acceleration/deceleration).

Press the key to change the parameter to (automatic torque

boost).

Press the ENTER key to display the parameter setting.