E6580757

M-7

13

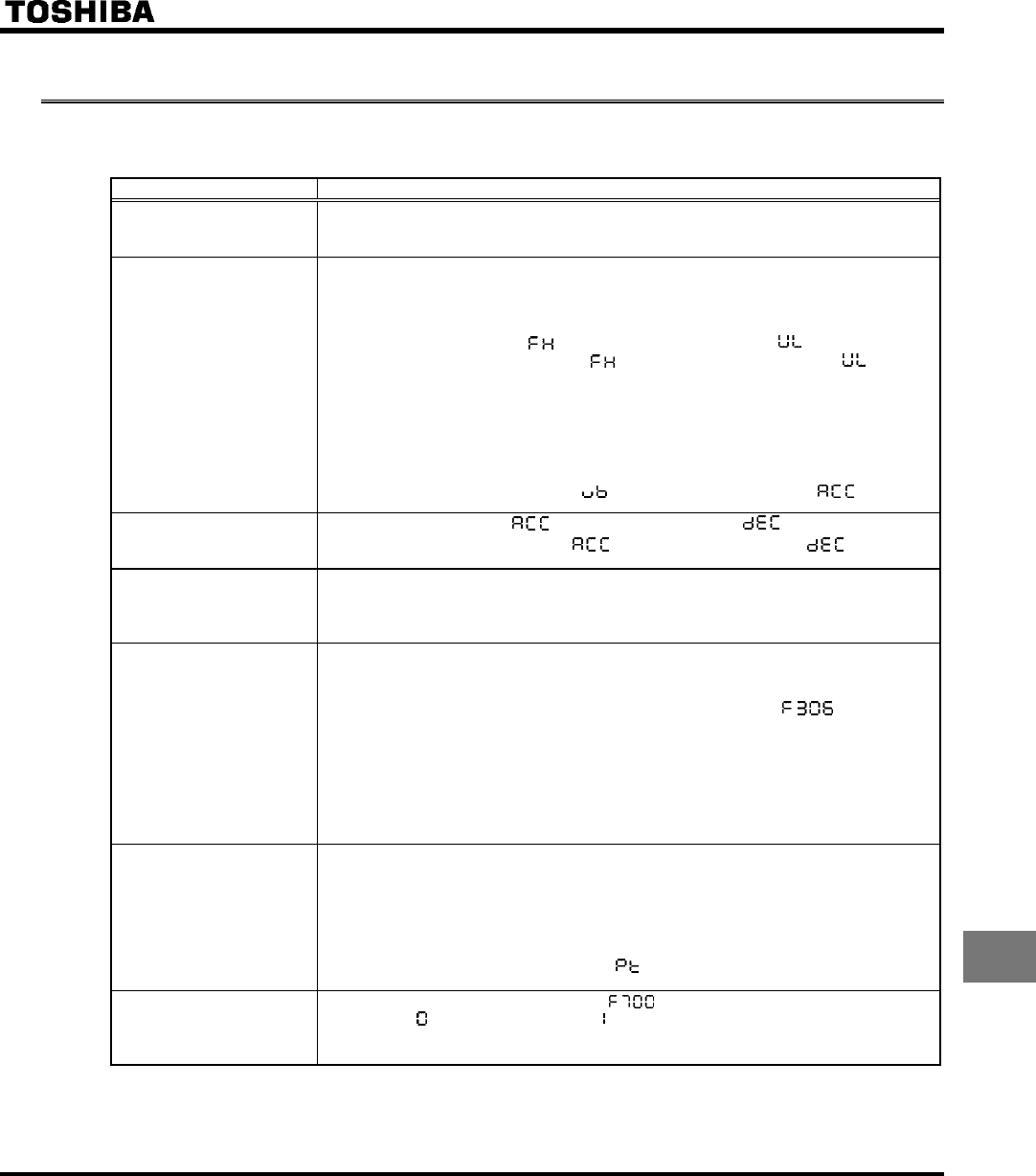

13.4 How to determine the causes of other problems

The following table provides a listing of other problems, their possible causes and remedies.

Problems Causes and remedies

The motor runs in the

wrong direction.

• Invert the phases of the output terminals U, V and W.

• Invert the forward/reverse run-signal terminals of the external input device. (See

6.3 "Assignment of functions to control terminals".)

The motor runs but its

speed does not change

normally.

• The load is too heavy.

Reduce the load.

• The soft stall function is activated.

Disable the soft stall function. (See 5.14.)

• The maximum frequency and the upper limit frequency are set too low.

Increase the maximum frequency and the upper limit frequency .

• The frequency setting signal is too low.

Check the signal set value, circuit, cables, etc.

• Check the setting characteristics (point 1 and point 2 settings) of the frequency

setting signal parameters. (See 6.5.)

• If the motor runs at a low speed, check to see that the stall prevention function is

activated because the torque boost amount is too large.

Adjust the torque boost amount ( ) and the acceleration time ( ). (See

5.12 and 5.1.)

The motor does not ac-

celerate or decelerate

smoothly.

• The acceleration time ( ) or the deceleration time ( ) is set too short.

Increase the acceleration time ( ) or the deceleration time ( ).

A too large current flows

into the motor.

• The load is too heavy.

Reduce the load.

• If the motor runs at a low speed, check whether the torque boost amount is too

large. (See 5.13.)

The motor runs at a

higher or lower speed

than the specified one.

• The motor has an improper voltage rating.

Use a motor with a proper voltage rating.

• The motor terminal voltage is too low.

Check the setting of the base frequency voltage parameter ( ). (See

6.12.6.)

Replace the cable with a cable larger in diameter.

• The reduction gear ratio, etc., are not set properly.

Adjust the reduction gear ratio, etc.

• The output frequency is not set correctly.

Check the output frequency range.

• Adjust the base frequency. (See 5.11.)

The motor speed fluctu-

ates during operation.

• The load is too heavy or too light.

Reduce the load fluctuation.

• The inverter or motor used does not have a rating large enough to drive the

load.

Use an inverter or motor with a rating large enough.

• Check whether the frequency setting signal changes.

• If the V/F control selection parameter is set at 3, check the vector control

setting, operation conditions, etc. (See 5.12.)

Parameter settings can-

not be changed.

• Change the setting of the parameter (prohibition of change of parameter

setting) to (permitted) if it is set at (prohibited).

For reasons of safety, some parameters cannot be reprogrammed while the

inverter is running.