EPSON Stylus Pro 7600/9600 Revision A

Adjustment Self-diagnostic Function 230

5.2.3 Adjustment

Make the mechanism adjustment (head slant) and the firmware parameter adjustment.

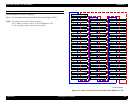

Figure 5-17. Adjustment Menu Transition

Table 5-19. Panel Setting Item List

Item Description See

Rear AD Adjustment Make the AD adjustment of the rear sensor. p.231

Edge AD Adjustment Make the AD adjustment of the edge sensor. p.232

Front AD Adjustment (Not used) –

Head Rank Input Input the characteristic values for the installed head.

After that, supply ink.

p.233

D/A Compensation Value

Write

(Not used)

p.236

Head Nozzle Check Check the print result for proper ink discharge from

the head nozzles.

p.237

Paper Skew Check Perform paper feed, and check the degree of skew by

sensor.

p.238

Feed Correction + T&B Make the printer perform printing and correct the

paper feed rate (band feed).

p.239

Top & Bottom Adjust the paper top and bottom margins and the left

margin.

p.242

Automatic Mechanism

Adjustment

(Not used)

–

Rear Paper Sensor Position Using cut paper, determine the distance between the

XF sensor and the XR sensor.

p.243

Platen Position Adjustment Adjust the sponge position of the platen. p.244

Platen Position Checking Check the adjustment result of the sponge position of

the platen.

p.245

Cutter Adjustment (Not used) –

Slant Check Make the printer perform printing and check the slant

of the head. (Mechanism Adjustment)

p.246

Round Trip Print Position

Adjustment (Bi-D)

Make the printer perform printing and adjust the

round trip printing position. (PG/1.2mm)

p.248

Parameter Copying

(Bi-D)

Copy the Bi-D adjustment value (PG/1.2mm) above

onto Bi-D2 (PG=0.7mm) and Bi-D3 (PG=2.1mm).

p.251

Round Trip Print Position

Adjustment 2 (Bi-D2)

Make the printer perform printing and adjust the

round trip printing position. PG/0.7mm

p.251

Round Trip Print Position

Adjustment 3 (Bi-D3)

Make the printer perform printing and adjust the

round trip printing position. PG/2.1mm

p.251

Round Trip Print Position (Bi-

D Adjustment) Checking

According to the result of the round trip print position

adjustment, shift the pattern by the theoretically

required number of dots. Then print the pattern and

make certain that the result of adjustment is proper.

p.252

Head Gap Adjustment

(Uni-D Adjustment)

Make the printer perform printing and adjust the one-

way printing position.

p.253

Test Pattern Printing Head nozzle checking and adjustment pattern (Input

the serial number)

p.255

Clean Head Clean the tube and head using cleaning liquid. p.256

Counter Clear Clear various software counters. p.257

Table 5-19. Panel Setting Item List (continued)

Item Description See

Adj :

? Rear AD ?

Adj :

? Edge AD ?

Adj :

? Frnt AD ?

Adj :

? Check Skew ?

Adj :

? Write D/A Value ?

Adj :

? Check Nozzle ?

Adj :

? Bi-d ?

Adj :

? CopyParam.

Adj :

? Bi-d2 ?

Adj :

? Bi-d3 ?

Adj :

? Bi-d Chk. ?

Adj :

? Head LR Adj.

Adj :

? Test Print ?

Adj :

? Clean Head ?

Adj :

? Counter Clear ?

[SelecType]

[Pause] or [Items]

[Enter] Start

Press Enter after the last item

Adj :

? Input Rank ?

Adj :

? Feed Adj.+T&B ?

Adj :

? Top & Bottom ?

Adj :

? AT MechaAdj. ?

Adj :

? Rear Sensor Pos. ?

Adj :

? Platen Pos. ?

Adj :

? Platen Pos. Chk. ?

Adj :

? Cut Adj ?

Adj :

? Head Slant ?

*Not Used

*Not Used

*Not Used

*Not Used