Printing from the MP Tray (Tray 1)

MP tray selection is provided by the Formatter PCA, as

configured by the operator’s control panel or by a software

application. The MP tray (Tray 1) feed system’s paper motion

begins when the DC Controller PCA, after receiving a

PRNT

signal, starts the Scanner Motor (M5) and the Main Motor (M1).

When the fusing roller reaches the minimum operating

temperature (183° C), the MP pickup roller clutch solenoid (SL2)

is energized for 1 second, allowing the MP pickup roller to make

one rotation. Clutches and solenoids work together to start and

stop gears and rollers used for paper movement. The MP pickup

roller then feeds a sheet of paper from the MP tray (Tray 1).

The Formatter PCA sends the

VDO signal to the print engine

within a specific time period after the paper reaches the

Input/Registration Paper Sensor (PS1). This aligns the leading

edge of the toner image on the photosensitive drum with the

leading edge of the paper. After the paper passes the drum and

the fusing rollers, it triggers the Paper Exit Sensor (PS3). The

paper then is directed to the output tray.

If the paper does not reach or clear each sensor within a specified

time, the microprocessor on the DC Controller PCA assumes a

paper jam occurred and informs the Formatter PCA.

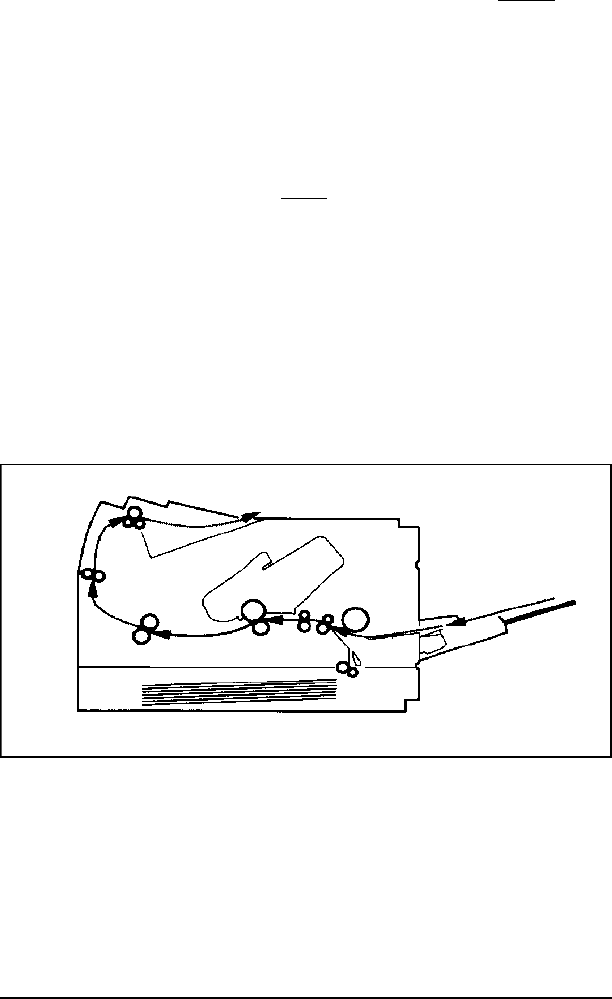

Figure 5-18 MP Tray (Tray 1) to Output Tray Paper Path

Functional Overview 5-29