Table 6-2 describes the screws used in the printers, and provides

guidelines to help determine where each type of screw is used.

The screws can vary in length depending on the thickness of the

material being fastened.

Typically, plated screws are used in areas visible to the customer,

and black screws are used in all other areas of the printer.

Always note where each type of screw is located and replace each

one into its original location.

Caution

To install a self-tapping screw, first turn it

counter-clockwise to align it with the existing

thread pattern, then carefully turn clockwise to

tighten. Do not over-tighten. If a self-tapping

screw-hole strips, repair of the screw-hole or

replacement of the affected assembly is required.

In the removal and replacement procedures that follow, the

number inside the parentheses, such as (4), refers to the number

of screws you must remove.

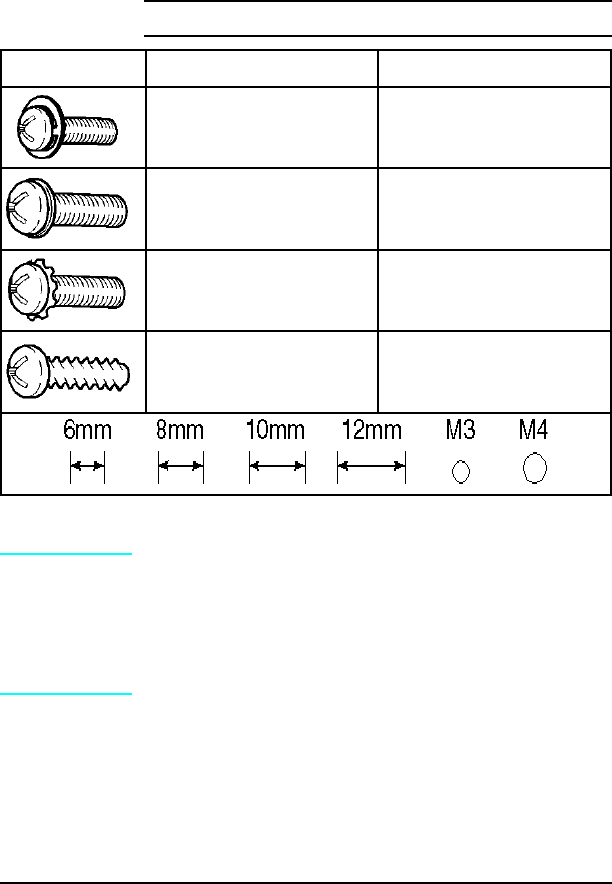

DRAWING DESCRIPTION PURPOSE

Threaded Phillips screw with

lock and flat washer

Used to fasten metal or plastic

to threaded plastic or metal.

Threaded Phillips washer head

screw

Used to fasten metal or plastic

to metal when high torque is

required.

Threaded Phillips w/captive

star washer

Used to fasten metal to metal

when good electrical contact is

needed.

Self-tapping Phillips screw Used to fasten metal or plastic

to plastic mainframes.

Table 6-2 Printer Hardware Descriptions

Removal and Replacement 6-3