E6581528

11

K-16

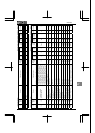

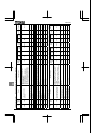

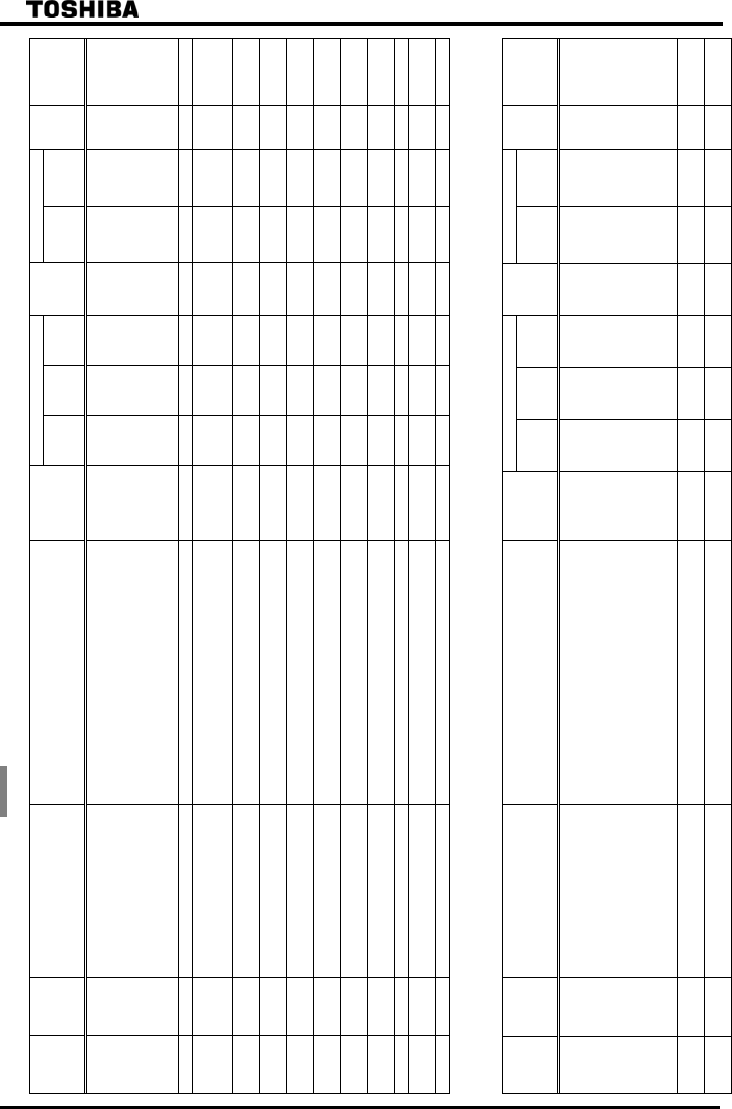

[18] Motor constant Sensorless vector/vector with sensor (●:Effective, -:Ineffective)

Default setting

Vector control

Title

Commun

i

cation

No.

Function Adjustment range

Minimum

setting unit

(Panel/Communi

cation)

=

500V

-50Hz

=

575V

-60Hz

=

690V

-50Hz

Write

during

running

Speed

control

Torque

control

V/f

Constant

Reference

0400 Auto-tuning 1

0:No auto-tuning

1:Initialize motor constant (0 after execution)

2:Continue operation continued after auto-tuning

(0 after execution)

3:Auto-tuning by input terminal signal

4:Motor constant auto calculation (0 after

execution)

1/1 0 0 0 Disabled ●/● ●/● - 6. 22

0401 Slip frequency gain 0~150% 1/1 70 70 70 Enabled ●/- - - 6. 22

0402 Cooled

0:Disabled

1:Self-cooled motor

2:Forced air-cooled motor

1/1 0 0 0 Disabled ●/● ●/● - 6. 22

0405

Motor rated capacity (motor

name plate)

0.1~800kW 0.1/0.1 *1 *1 *1 Disabled ●/● ●/● - 6. 22

0406

Motor rated current (motor

name plate)

0.1~2000A 0.1/0.1 *1 *1 *1 Disabled ●/● ●/● - 6. 22

0407

Motor rated rotational speed

(motor name plate)

100~60000min-1 *2 1/1 *1 *1 *1 Disabled ●/● ●/● - 6. 22

0410

Motor constant 1 (torque

boost)

0.0~30.0% 0.1/0.1 *1 *1 *1 Enabled ●/● ●/● - 6. 22

0411

Motor constant 2 (no load

current)

10~90% 1/1 *1 *1 *1 Disabled ●/● ●/● - 6. 22

0412

Motor constant 3 (leak

inductance)

0~200 1/1 *1 *1 *1 Disabled ●/● ●/● - 6. 22

0413 Motor constant 4 (rated slip) 0.1~25.0% 0.1/0.1 *1 *1 *1 Disabled ●/● ●/● - 6. 22

0415

Exciting strengthening

coefficient

100~130% 1/1 100 100 100 Disabled ●/● ●/● - 6. 23

0416 Stall prevention factor 10~250 1/1 100 100 100 Disabled ●/● ●/● - 6. 23

*1: Default values vary depending on the capacity. ⇒ See the table of K-46.

*2: If the speed of rotation is set at 10,000min

-1

or more, the error messages and (if the speed of rotation is set at 10,000min

-1

) are displayed alternately.

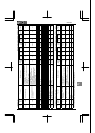

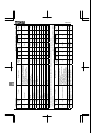

[19] Torque control [1/2] Sensorless vector/vector with sensor (●:Effective, -:Ineffective)

Default setting

Vector control

Title

Commun

ication

No.

Function Adjustment range

Minimum

setting unit

(Panel/Communi

cation)

=

500V

-50Hz

=

575V

-60Hz

=

690V

-50Hz

Write

during

running

Speed

control

Torque

control

V/f

Constant

Reference

0420 Torque command selection

1:VI/II (voltage/current input)

2:RR/S4 (potentiometer/voltage input)

3:RX (voltage input)

4:Operation panel input enabled (including

LED/LCD option input)

5:2-wire RS485 communication input

6:4-wire RS485 communication input

7:Communications option input enabled

8:Optional AI1 (differential current input)

1/1 3 3 3 Enabled - ●/● - *1

0423

Tension torque bias input

selection (torque control)

0:Disabled, 1~8 (same as ) 1/1 0 0 0 Enabled - ●/● - 6. 24. 3

0424

Load sharing gain input

selection

0:Disabled, 1~8 (same as ) 1/1 0 0 0 Enabled - ●/● - 6. 24. 3

*1: ⇒ For details, refer to Instruction Manual (E6581331) specified in Section 6.42.