E6581528

M-2

13

(Continued)

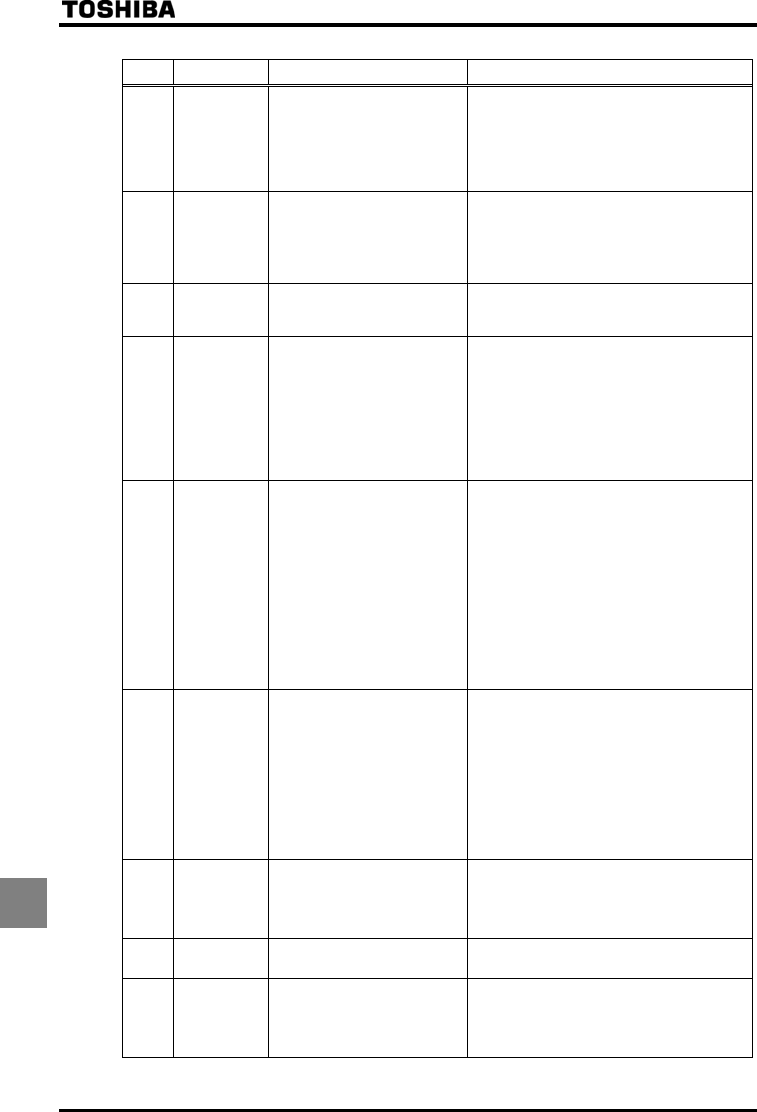

Error

code

Description Possible causes Remedies

Inverter

overload

•Rapid acceleration is operated.

•The DC braking amount is too

large.

•The V/f setting is improper.

•A restart signal is input to the

rotating motor after a momentary

stop, etc.

•The load is too large.

•Increase the acceleration time .

•Reduce the DC braking amount and the

DC braking time .

•Check the V/f parameter setting.

•Use (Auto-restart) and (Regenerative

power ride-though control).

•Use an inverter with a larger rating.

Motor overload

•

The V/f parameter is improperly

set.

•The motor is locked up.

•Low-speed operation is performed

continuously.

•An excessive load is applied to the

motor during operation.

•Check the V/f parameter setting.

•Check the load (operated machine).

•Check the setting and adjust

according to the sustainable overload in the motor

low-speed range.

•Reduce the DC braking amount and the

DC braking time .

Dynamic

braking resistor

overload

•Rapid deceleration is operated.

•Dynamic braking is too large.

•Increase the deceleration time .

•Increase the capacity of dynamic braking resistor

(wattage) and adjust PBR capacity parameter

.

Overvoltage

during

acceleration

•

The input voltage fluctuates abnormally.

(1)The power supply has a capacity

of 500kVA or more.

(2)A power factor improvement

capacitor is opened and closed.

(3)A system using a thyrister is

connected to the same power

distribution line.

•A restart signal is input to the

rotating motor after a momentary

stop, etc.

•Insert a suitable input reactor.

•Use (Auto-restart) and (Regenerative

power ride-though control).

Overvoltage

during

deceleration

•

The deceleration time

is too

short (regenerative energy is too

large).

•The dynamic braking resistor has

a considerably large resistance.

•

(Dynamic braking resistor) is OFF.

Overvoltage limit operation

is OFF.

•

The input voltage fluctuates abnormally.

(1)The power supply has a capacity

of 500kVA or more.

(2)A power factor improvement

capacitor is opened and closed.

(3)A system using a thyrister is

connected to the same power

distribution line.

•Increase the deceleration time .

•Install a dynamic braking resistor.

•Decrease dynamic braking resistance. (Also reset

the .)

•Set dynamic braking mode parameter

properly.

•Set overvoltage limit operation properly.

•Insert a suitable input reactor.

Overvoltage

during fixed

speed operation

•The input voltage fluctuates

abnormally.

(1)The power supply has a capacity

of 500kVA or more.

(2)A power factor improvement

capacitor is opened and closed.

(3)A system using a thyrister is

connected to the same power

distribution line.

•The motor is in a regenerative

state because the load causes the

motor to run at a frequency higher

than the inverter output frequency.

•Insert a suitable input reactor.

•Install a dynamic braking resistor.

* Overtorque

•Overtorque reaches to a detection

level during operation.

•Stall prevention operation was

performed continuously for a

length of time longer than that set

with .

•Check system error.

•Check whether the motor is overloaded or the

brake is engaged.

*

Low current

operation

•The output current decreased to a

low-current detection level during

operation.

•Check the suitable detection level for the system

().

•Make a service call if the setting is correct.

*

Undervoltage

(main circuit)

•The input voltage (in the main

circuit) is too low.

•Momentary power failure occurs

because undervoltage continues

longer than undervoltage detection

time .

•Check the input voltage.

•To cope with a momentary stop due to

undervoltage, enable (Regenerative power

ride-through control), (auto-restart control),

and (Undervoltage detection time).

*Presence or absence of parameter trip can be selected.

(Continued overleaf)