E6581528

M-5

13

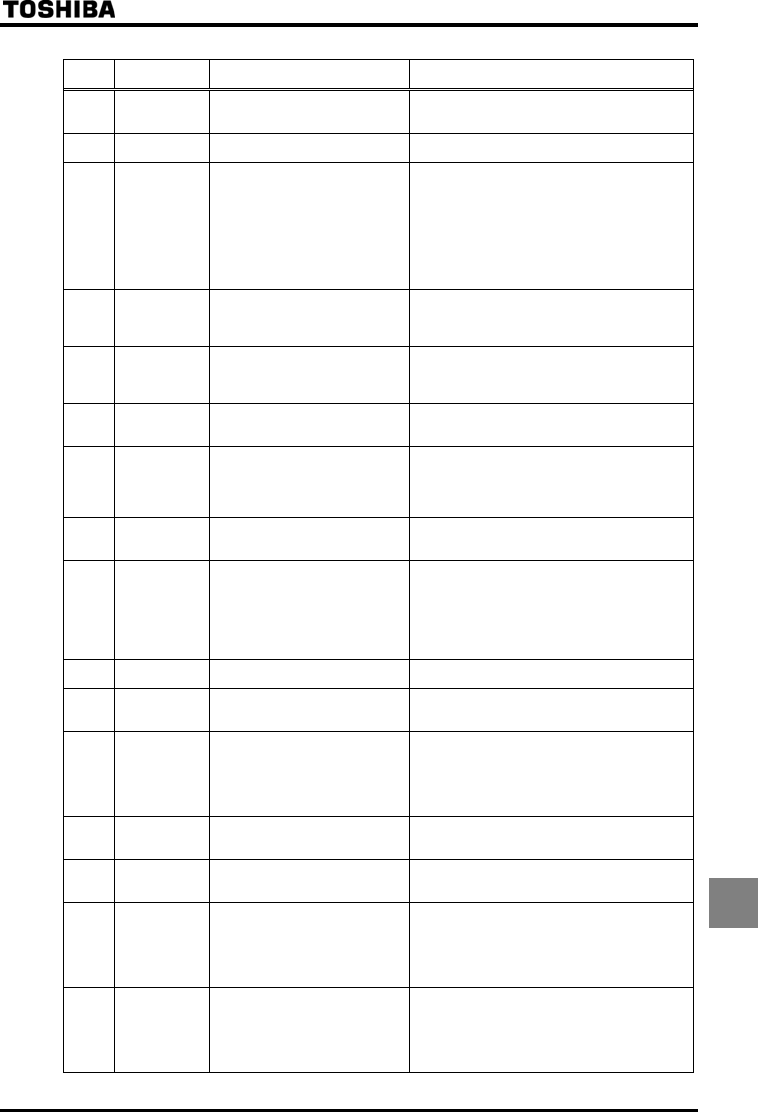

[Alarm] The following are messages only. No trip is developed.

Error

code

Problem Possible causes Remedies

ST signal OFF

•ST terminal (terminal to which the

ST function is assigned) is in

open-circuit.

•Close ST (terminal to which the ST function is

assigned)-CC circuit.

PWR signal

OFF

•PWR terminal is in open-circuit. •Close PWR-P24/PLC circuit.

Control power

backup

undervoltage

•The control voltage between +SU

and CC terminals is too low.

•Control power is not supplied

through +SU and CC terminals.

•The parameter is not set

correctly.

•Check whether the voltage between +SU and CC

terminals is DC20V or more.

•Set to if a control power backup device

is not connected to +SU and CC terminals.

In the event of a error, the inverter will not

be reset automatically even if the control voltage

between +SU and CC terminals returns to its

normal level. To reset the inverter, turn it off and

then back it on.

Undervoltage in

main circuit

•The supply voltage between R, S

and T is under voltage.

•Trouble of rush current restraint

circuit or DC circuit fuse.

•Measure the main circuit supply voltage.

If the voltage is at a normal level, the inverter

requires repairing.

•Make a service call.

Retry

•The inverter is in the process of

retry.

•A momentary stop occurred.

•The inverter is normal if it restarts after several

tens of seconds. The inverter restarts

automatically. Be careful of the machine because

it may suddenly restart.

Point setting

alarm

•The frequency setting signals at

points 1 and 2 are set too close to

each other.

•Set the frequency setting signals at points 1 and 2

apart from each other.

Clear enabling

indication

•This message is displayed when

pressing the STOP key while an

error code is displayed.

•Input terminal RES signal is ON

during trip display.

•Press the STOP key again to clear the trip.

•Turn off the input terminal RES signal.

Emergency stop

enabling

indication

•The operation panel is used to

stop the operation in automatic

control or remote control mode.

•Press the STOP key for an emergency stop. To

cancel the emergency stop, press any other key.

/

Setting error

alarm

An error code

and data are

displayed

alternately twice

each.

•An error is found in a setting when

data is reading or writing.

•Check whether the setting is made correctly.

DC braking

•DC braking in process •The message goes off in several tens of seconds

if no problem occurs. [Note]

Shaft fixing in

control

•Motor shaft fixing control is in

process.

•If the message disappears by stop command (ST

(terminal to which the ST function is assigned)-CC

open), it is normal.

Panel indication

overflow

•The digit number of the item

displayed, e.g., frequency, is in

excess of the specified digit

number.

(Number of overflowing digits is

indicated.)

•For indication of frequency, set multiplying rate

() lower. (Parameter setting that results in

overflow is of course valid.)

Parameters in

the process of

initialization

•Parameters are being initialized to

default values.

•Normal if the message disappears after a while

(several seconds to several tens of seconds).

In auto-tuning 1

•Auto-tuning 1 in process. •Normal if it the message disappears after a few

seconds for 6900PL or less, and 2 or 3 minutes for

6110KPC or larger.

Auto-stop

because of

continuous

operation at the

lower-limit

frequency

•The automatic stop function of

is being performed.

•This function is deactivated when the command

frequency becomes 0.2Hz or more higher than the

lower-limit frequency (LL) or when a command for

stopping operation is entered.

Momentary

power failure

slowdown stop

prohibition

function

activated.

•The deceleration stop function of

(regenerative power

ride-through control) is activated.

•To restart operation, reset the inverter or input an

operation signal again.

(Continued overleaf)