E6581528

11

K-18

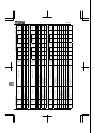

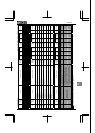

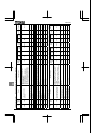

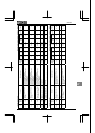

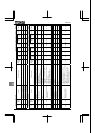

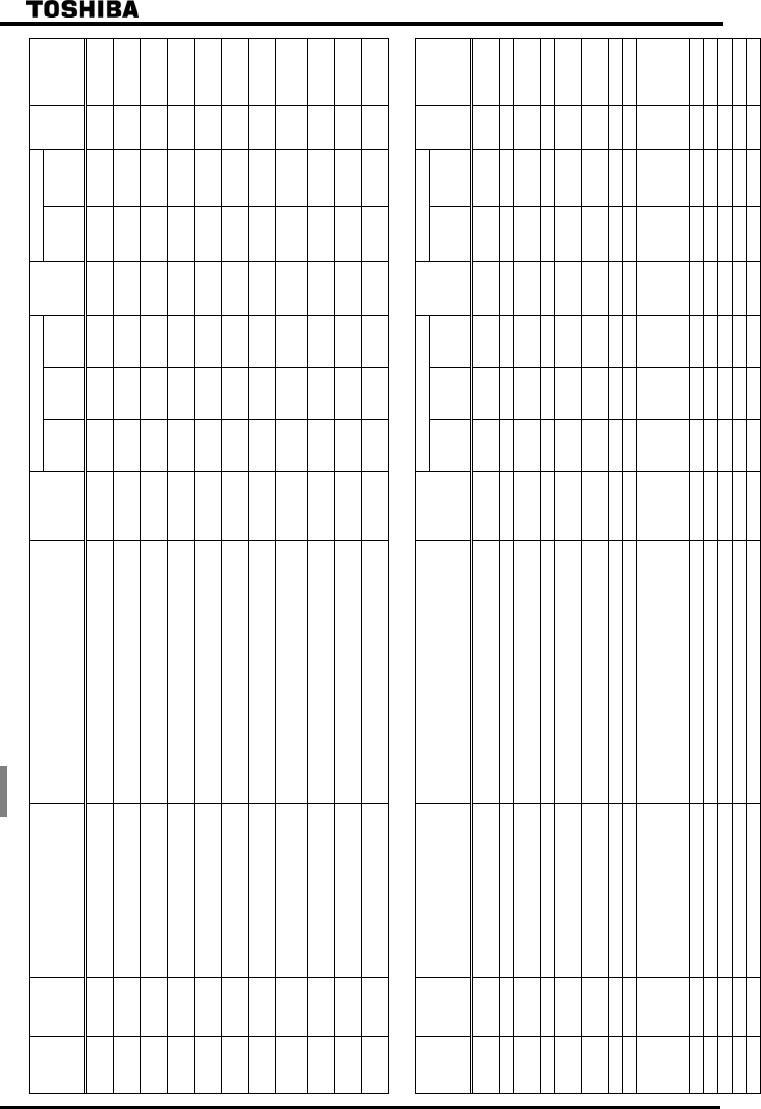

[20] Torque limit [2/2] Sensorless vector/vector with sensor (●:Effective, -:Ineffective)

Default setting

Vector control

Title

Commun

ication

No.

Function Adjustment range

Minimum

setting unit

(Panel/Communi

cation)

=

500V

-50Hz

=

575V

-60Hz

=

690V

-50Hz

Write

during

running

Speed

control

Torque

control

V/f

Constant

Reference

0443

Regenerative braking torque

limit 1 level

0.0~249.9%, 250.0:Disabled 0.1/0.01 250.0 250.0 250.0 Enabled ●/● ●/● - 6. 25. 1

0444

Power running torque limit 2

level

0.0~249.9%, 250.0:Disabled 0.1/0.01 250.0 250.0 250.0 Enabled ●/● ●/● - 6. 25. 1

0445

Regenerative braking torque

limit 2 level

0.0~249.9%, 250.0:Disabled 0.1/0.01 250.0 250.0 250.0 Enabled ●/● ●/● - 6. 25. 1

0446

Power running torque limit 3

level

0.0~249.9%, 250.0:Disabled 0.1/0.01 250.0 250.0 250.0 Enabled ●/● ●/● - 6. 25. 1

0447

Regenerative braking torque

limit 3 level

0.0~249.9%, 250.0:Disabled 0.1/0.01 250.0 250.0 250.0 Enabled ●/● ●/● - 6. 25. 1

0448

Power running torque limit 4

level

0.0~249.9%, 250.0:Disabled 0.1/0.01 250.0 250.0 250.0 Enabled ●/● ●/● - 6. 25. 1

0449

Regenerative braking torque

limit 4 level

0.0~249.9%, 250.0:Disabled 0.1/0.01 250.0 250.0 250.0 Enabled ●/● ●/● - 6. 25. 1

0451

Acceleration/deceleration

operation after torque limit

0:In sync with acceleration/deceleration

1:In sync with min. time

1/1 0 0 0 Disabled ●/● - - 6. 25. 2

0452

Power running stall continuous

trip detection time

0.0~1.0 sec. 0.1/0.1 0.0 0.0 0.0 Enabled ●/● - ● 6. 26. 1

0453

Regenerative braking stall

prevention mode selection

0:Stall during regenerative braking

1:Not stall during regenerative braking

1/1 0 0 0 Enabled ●/● - ● 6. 26. 2

0454

Constant output zone torque

limit selection

0:Constant output limit

1:Constant torque limit

1/1 0 0 0 Disabled ●/● ●/● - 6. 25. 1

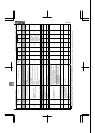

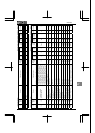

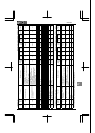

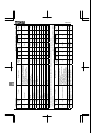

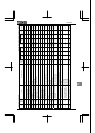

[21] Adjustment parameters [1/2] Sensorless vector/vector with sensor (●:Effective, -:Ineffective)

Default setting

Vector control

Title

Commun

ication

No.

Function Adjustment range

Minimum

setting unit

(Panel/Communi

cation)

=

500V

-50Hz

=

575V

-60Hz

=

690V

-50Hz

Write

during

running

Speed

control

Torque

control

V/f

Constant

Reference

0458

Current control proportional

gain

0~100 1/1 0 0 0 Disabled ●/● ●/● - *1

0460 Speed loop proportional gain 1~9999 1/1 12 12 12 Enabled ●/● - - *1

0461

Speed loop stabilization

coefficient

1~9999 1/1 100 100 100 Enabled ●/● - - *1

0462 Moment of inertia of load 1

0~100 1/1 35 35 35 Enabled ●/● - - *1

0463

Second speed loop proportional

gain

1~9999 1/1 12 12 12 Enabled ●/● - - *1

0464

Second speed loop

stabilization coefficient

1~9999 1/1 100 100 100 Enabled ●/● - - *1

0465 Moment of inertia of load 2 0~100 1/1 35 35 35 Enabled ●/● - - *1

0466 Speed PI switching frequency 0.0~ Hz 1/1 0.0 0.0 0.0 Enabled ●/● - - *1

0467 Motor oscillation control

0:Disabled

1:Enabled(Low gain)

2:Enabled(Middle gain)

3:Enabled(High gain)

1/1 0 0 0 Disabled -/- -/- ● 6.27.2

0470 VI/II input bias 0~255 1/1 *2 *2 *2 Enabled ●/● ●/● ● 6. 28

0471 VI/II input gain 0~255 1/1 *2 *2 *2 Enabled ●/● ●/● ● 6. 28

0472 RR/S4 input bias 0~255 1/1 *2 *2 *2 Enabled ●/● ●/● ● 6. 28

0473 RR/S4 input gain 0~255 1/1 *2 *2 *2 Enabled ●/● ●/● ● 6. 28

0474 RX input bias 0~255 1/1 *2 *2 *2 Enabled ●/● ●/● ● 6. 28

*1: ⇒ For details, refer to Instruction Manual (E6581333) specified in Section 6.42. *2: ⇒ Settings vary from unit to unit. Even if is set to , no change is made to these values.