Strain Sensors The metal foil resistance strain gage is by far the most

widely used strain measurement sensor. It consists of a thin metallic

foil grid bonded to a thin insulating, adhesive backing. The resistance of

the foil varies linearly with strain. Strain in the test body is simply the

ratio of the foil’s strained to unstrained resistance:

ε = ∆R / R.

The Gage Factor (

GF) indicates the sensitivity of a strain gage and is a

measure of the fractional resistance change per strain:

GF = (∆R / R) / ε .

Devices with a higher gage factor will exhibit a greater resistance

change per strain applied.

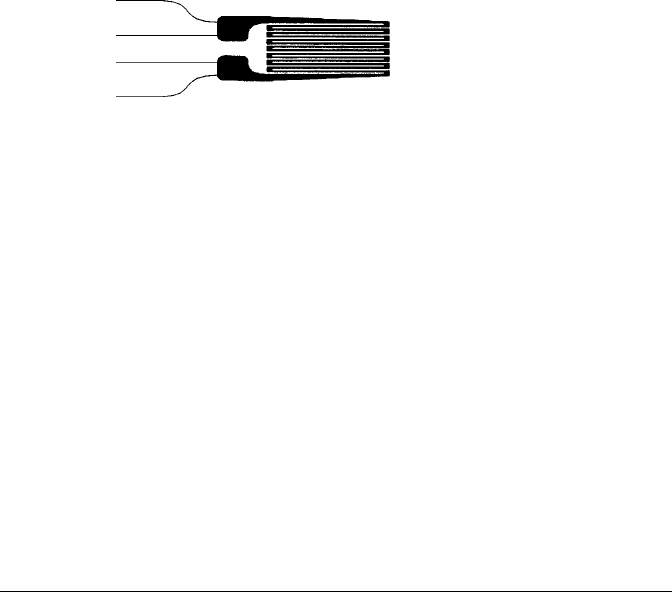

Strain gages are available in many patterns with various numbers and

configurations of elements. The most common element is the single gage

form shown below. Multi-element strain gages, also called rosettes, are

used to measure components of strain in different directions.

Two-element (90

°) and three-element (45° or 60°) configurations are the

most common.

Common Uses for Strain Gages Strain gages are used to sense many

types of physical parameters. Strain gages are primarily a force-sensing

device. Force is measured indirectly by measuring the deformation of a

test body to a known applied force thus producing a resistance change

proportional to the applied force. Many other physical quantities can be

measured through force measurements. Common applications of strain

gages include weight, pressure, flow, and level measurements.

HI Source

HI Sense

LO Sense

LO Source

Chapter 8 Tutorial

Measurement Fundamentals

374