F-44 F-44

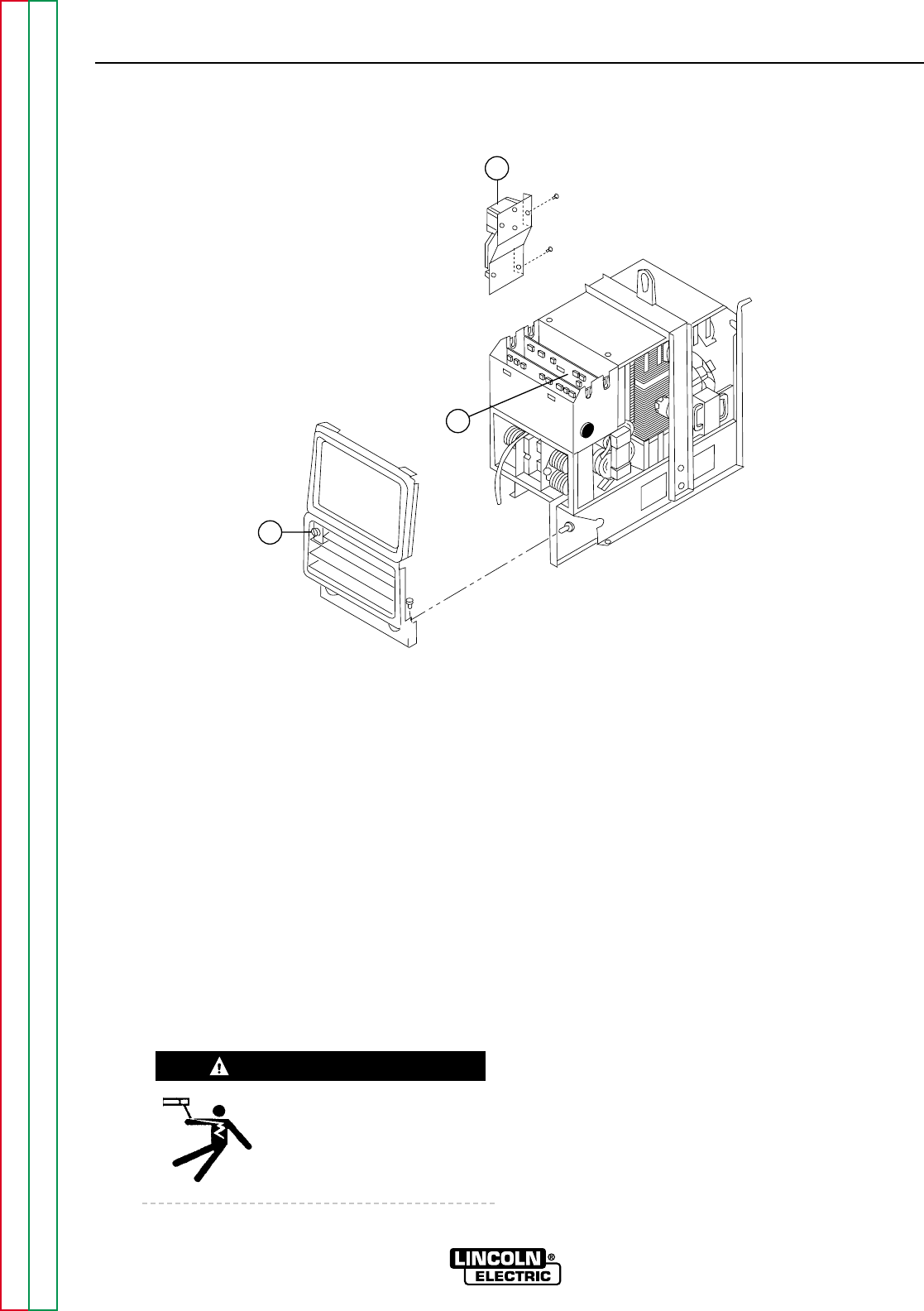

INPUT POWER AND WIRING HARNESS TEST

FIGURE F.13 - INPUT POWER INSPECTION POINTS

1

2

3

TROUBLESHOOTING & REPAIR

TEST PROCEDURE

1. Remove main input supply power to the

machine.

2. With the 3/8" nut driver, remove the 4

screws that hold the handle to the machine.

3. Remove the rubber gasket (cover seal) from

the lift bail.

4. With the 5/16" nut driver, remove the sheet

metal screws from the case top.

5. With the 5/16" nut driver, remove the

screws holding the right and left case sides.

Remove the case sides by lifting up and

out.

6. Perform the Capacitor Discharge Pro-

cedure described earlier in this section of

the manual.

Before continuing with the

test procedure, perform the

capacitor discharge proce-

dure to avoid electric shock.

7. After you have completed the capacitor dis-

charge procedure for all four switch boards,

remove the PC board cover. Use the 5/16"

nut driver.

8. Manually check the power switch (S1) for

proper operation by turning it back and

forth. At the back of the front panel where

the switch is mounted, make a visual

inspection. Be sure the input and output

leads are not shorted together. Make sure

the switch contacts are not fused together

or shorted to another phase. (Because of

the high input voltage involved, you should

be able to see physical evidence if any of

these problems exist.) Remove the tape

covering the switch and check the switch

with an ohmmeter. High resistance should

be present.

POWER WAVE 450

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

WARNING

1. POWER SWITCH (S1)

2. MAIN CONTACTOR INPUT LEADS (TOP)

3. PROTECTION BOARD