TROUBLESHOOTING & REPAIR

F-206 F-206

POWER WAVE 450

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

PRE-POWERUP SWITCH BOARD TEST PROCEDURE

FOR REPLACEMENT OF SWITCH ASSEMBLY G2402-2 (continued)

460VAC RECONNECT

1. Reconfigure the machine for 460VAC operation.

2. Turn ON the variable AC supply applied to the

primary circuit. See Figure F.76.

3. Turn on the arc start switch. See Arc Start

PW450 or Figure F.79.

4. Slowly increase the voltage until filter capacitor

voltage is 25VDC. NOTE: Monitor both capaci-

tor voltages. If the two voltages are not within 5

to 8 VDC of each other STOP and check wiring

to the FET switch board assembly and also the

individual switch boards. See Figure F.77.

5. Adjust the grid load to get 5 amps output from

the Power Source. DO NOT PULL MORE

THAN 7-8 AMPS OUTPUT FROM THE

POWER WAVE.

6. Repeat the previous Snubber Signal Test by

checking the eight test points.

OUTPUT SIGNAL TEST

1. Make certain the machine is configured for

460VAC operation.

2. Turn ON the variable AC supply applied to the

primary circuit. See Figure F.76.

3. Turn ON the arc start switch. See Arc Start

PW450 or Figure F.79.

4. Slowly increase the voltage until the filter capac-

itor voltage is 25VDC. See Figure F.77.

5. Adjust the grid load to get 5 amps output from

the Power Wave. DO NOT DRAW MORE

THAN 7-8 AMPS OUTPUT FROM THE

POWER WAVE.

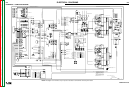

6. Set the Oscilloscope for:

5 V/div.

10 uS/div.

ALL METERS AND OSCILLOSCOPES MUST BE

ELECTRICALLY ISOLATED.

7. Connect the positive oscilloscope probe to the

Power Wave positive welding output terminal

and the negative probe to the negative welding

output terminal. The output should look like the

oscilloscope picture in Figure F.83.

WARNING

FIGURE F.82 - SNUBBER SIGNAL

0 V

5V/Div

20uS/Div