3–89

OPERATIONS AND TIMING

COPYRIGHT

©

1998 CANON INC. CANON NP6621 REV.0 FEB. 1998 PRINTED IN JAPAN (IMPRIME AU JAPON)

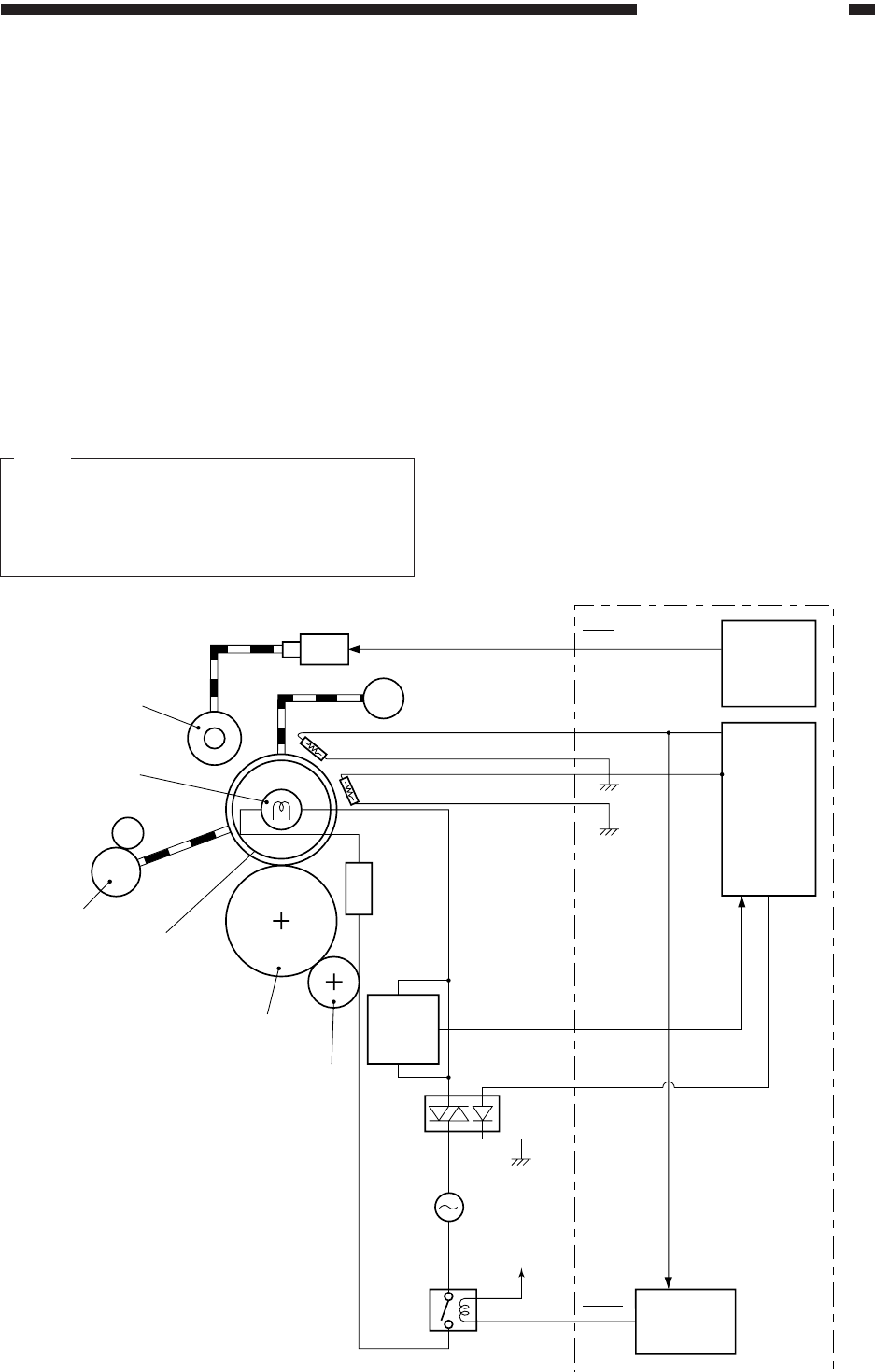

The copier is equipped with three protection

mechanisms to prevent the fixing heater from going

ON at wrong timing.

• The microprocessor monitors the voltage of

TH1 and indicates ‘E000’ or ‘E001’ or ‘E002’

or ‘H003’ in response to an error.

• If the voltage of TH1 and TH2 falls below

about 0.9 V (equivalent of 215°C), the error

detection circuit cuts off the supply power to

the fixing heater regardless of the output of

the microprocessor.

If the inside temperature of the thermal switch

rises above 220°C, the power to the fixing heater

will be off.

Note:

Once the contact of the thermoswitch (TS1)

opens, the thermoswitch cannot be used unless

cooled to 0°C or less; the contact will not recover

at ambient temperature.

2. Oil Application Roller

The upper fixing roller is provided with an oil

application roller for cleaning and application of oil.

Normally, the oil application roller remains away

from the fixing roller, and it comes into contact with

the upper fixing roller only when copy paper passes

through.

The mechanism is driven by the oil application

solenoid (SL6); SL6 goes ON 1 sec after the

registration roller goes ON; it then goes OFF as

soon as the main motor (M1) goes OFF thereby

bringing the oil application roller into contact with

the upper fixing roller.

Table 3-442

Thermoswitch

(220˚C)

Fixing heater

(H1)

Upper fixing roller

Delivery roller

Main motor

Thermistor(TH1);Main

Thermistor(TH2);Auxiliary

J324A-4

J324A- 1

J319- 1

-2

-3

-4

TH1

HTON

- 3 HTRD

J307-2

Microprocessor

(slave)

Microprocessor

(master)

Error detection

circuit

Oil application roller

Oil application solenoid

Lower fixing roller

Power supply

Relay(K1)

TS1

SSR

SSR ON

detection

24V

M1

SL6

DC controller PCB

ACOFF

SL6D

Cleaning roller