1

1

',

,I

,

,

t

t

i

t

sion rates,

as

computed

for

the

selected crystal

freq uency. Initialization would req uire the oper-

ator

to

hit

a specific

key

several times (usually the

"U"

key, which generates a

pattern

of

alternating

ones and zeros). The identification routine would

attempt

to

"read"

this

pattern

at

each baud rate,

in

turn,

until finding

the

rate at which the read

was successful.

The cassette recorder used to develop the tape

interface was a Lloyd's push-button model which

cost $17 in 1972. Empirical testing has indicated

that

for this application, the quality

of

the cassette

recorder

is

less critical than

the

quality

of

the

tape

itself. In

other

words, some

33~

cassettes were

not

very reliable, even when used with more expensive

recorders.

When using a cassette at the beginning

of

a side,

allow

the

tape to run for

about

10 seconds until

the

leader has passed before starting

to

write data.

Otherwise, data will be lost

to

the leader.

Depending

on

the

recorder quality, the tone

burst

freq uency and

duration

can be optimized for

higher

data

rates

by

modifying HALFCYC and

CYCNO. If so, CKRATE should also be reduced,

so

that

between

about

10 and

80

data samplings

are made during a single (one-third width)

tone

burst. At greatly increased frequencies, some

of

the

A1·43

components

in

the

analog interface might also be

modified.

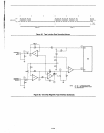

The two simple routines for recording

and

playing

back blocks

of

data

were intended

to

illustrate

one

way

of

using TAPEIN and TAPEO, and therefore

do

not

contain any provisions for

error

detection

or

correction. Depending on the nature

of

a partic-

ular application, these routines could be aug-

mented with parity bit or checksum comparison,

or

an

error

correcting code technique.

Funny

things happen when recording and playing

back a page

of

RAM which includes

the

subroutine

stack. Eventually, PLA YBK will

start

writing over

the

data at

the

top

of

the stack, destroying

the

subroutine traceback sequence. The

next

RET

instruction will then cause a

jump

to

a place where

you'd

rather

not

be.

The

printout

reproduced

in

the

CRT

Code inchides

the

assembled listings for

the

CRT

and magnetic

tape interfaces discussed

in

this application

note.

The object code produced was programmed

into

an 8755 EPROM, which was installed in the expan-

sion

PROM socket

of

the SDK-85 board. Some

very minor differences exist between this listing

and the code segments presented earlier, which

were written for

maximum

clarity.