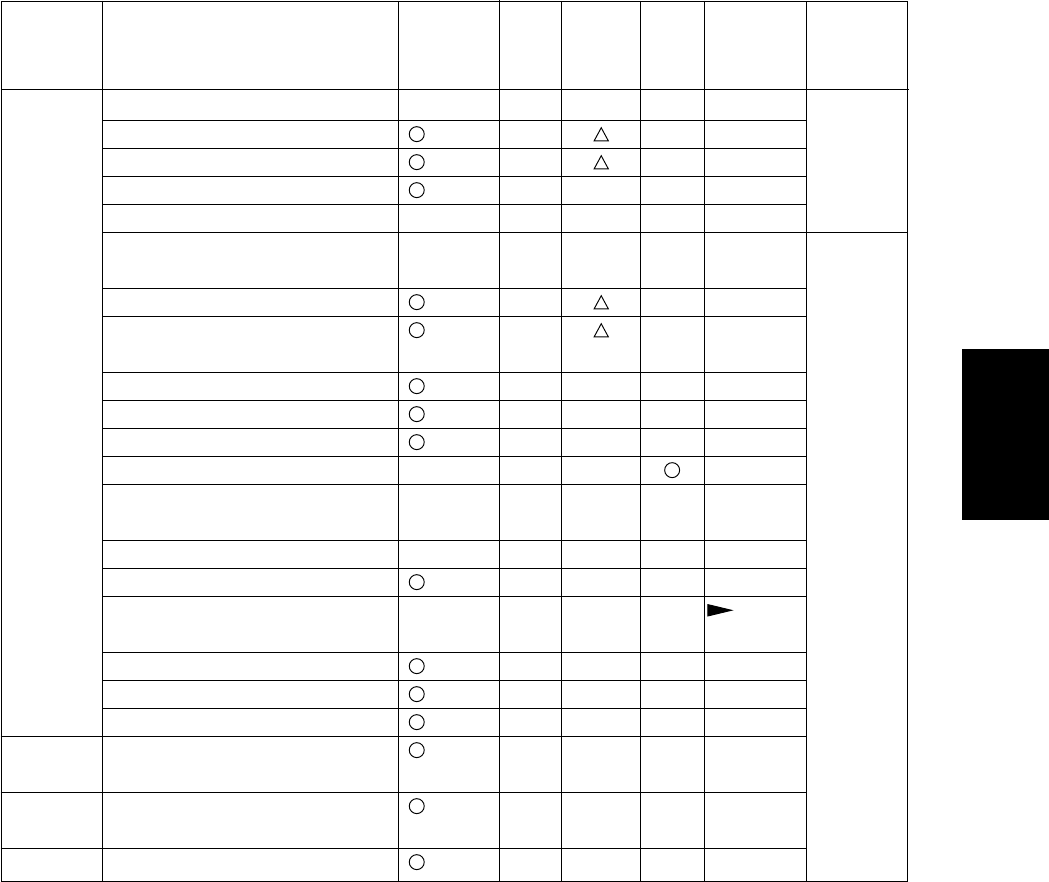

February 2002 © TOSHIBA TEC 3 - 5 FC-210/310 PREVENTIVE MAINTENANCE

Color Maintenance Checklist

1. Developer material (Y,M,C) 40/60 *8 Developer Y,

2. Doctor blade (40/60) *1 M,C counter

3. Developer unit drum seal (40/60) *9 (08-844,845,

4. Front/rear sides of developer unit (40/60) *2 846)

5. Oil seal portion AV

6. Drum cleaning blade 40/60 *3

<P23-I13>

7. Recovery blade (40/60) *4

Processing 8. Felt seals on both ends

(40/60) Drum Y,M,C

unit (EPU) of the cleaning blade life counter

9. Entire developer/cleaner unit (40/60) *7 (08-840,841,

(Color(Y,M,C)

10. Main charger case (40/60) *6 842)

related parts)

11.Discharge lamp (40/60)

12. Wire cleaning pad 40/60 <P22-I16> Note:

13. Main charger wire 40/60 *6 Clear "Drum

<P22-I15> Y,M,C drive

14. Main charger grid 40/60 <P22-I24> counter (08-

15. Main charger contact (40/60) 867,868,

16.Drum 40/60 ch.3.6.2 869)" when

<P22-I38> drums have

17. Drum shaft (40/60) been re-

18. Drum thermistor (Y) (40/60) placed.

19. Toner recovery auger drive (40/60) W

Image quality

37. Image quality sensor’s area (40/60) *11

control

Color 38.Color registration sensor (40/60)

registration

Laser unit 39. Slit glass (40/60)

Cleaning Lubri-

Replace- Opera-

Remarks Reference

Section Item to inspect

(X 1000) cation

ment tion

<P-I> counter

(X 1000) check