February 2002 © TOSHIBA TEC 2 - 11 FC-210/310 ADJUSTMENT

2.5.1 Paper alignment (paper buckle) at the registration roller

If the paper feed roller has prematurely become defective, it is possible to extend its service life, if

necessary, by increasing the aligning amount, as a temporary measure until a replacement becomes

available.

ADU

447

448

Long size

Short size

439

1st

cassette

2nd

cassette

3rd

cassette

4th

cassette

440

441

Copier cassettes

442

443

444

445

446

LCF

449

Bypass

feeding

450

Thick

paper2

451

Thick

paper3

452

OHP bypass

feeding

492

<Operation procedure> (Use codes 439 to 452 and 492 in adjustment mode (05).)

0 5

Power OFF/ON

Paper

source code

POWER

Digital keys

SET

( ENERGY SAVER

INTERRUPT

(Select a paper source)

START

START )

(Current value displayed)

or

(Stored in memory)

(Enter a new value.)

Digital keys

(Test copy)

(1)

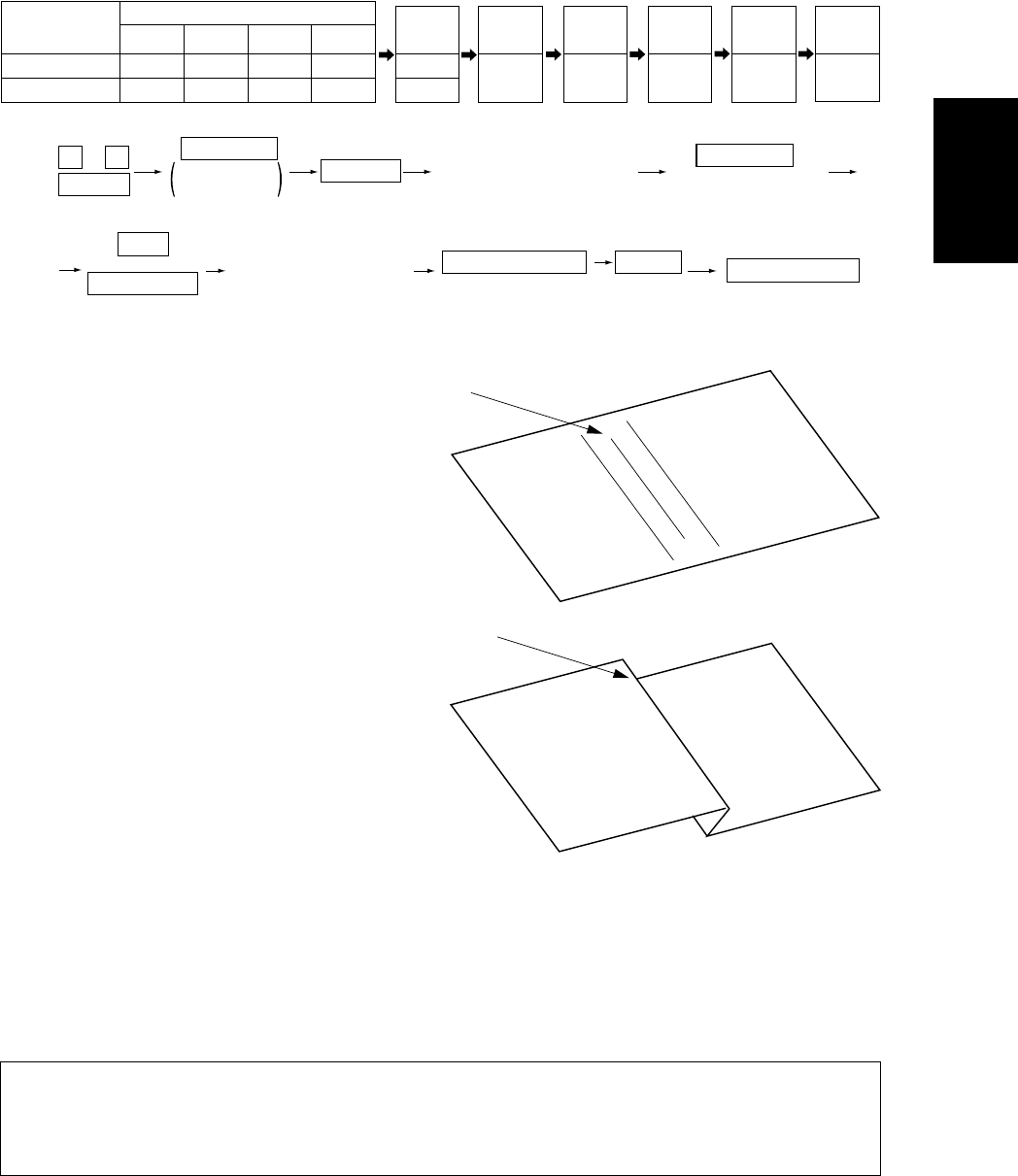

(2) Check for any transfer void or “Z” fold. If a trans-

fer problem is present, try the values in de-

scending order as “31”ৎ“30”ৎ“29”··· until the

transfer void disappears. At the same time,

confirm that any paper jam has not occurred.

Also, when the aligning amount has been in-

creased, this may increase the scraping sound

which occurs when the paper scrapes on the

mylar sheet as it is transferred by the registra-

tion roller. If this scraping sound is irritating,

try reducing the aligning amount.

(3) Do the same for ADU, LCF, bypass feeding,

thick paper 2, thick paper 3 and OHP bypass

feeding.

Transfer void

“Z” fold

Note:

When paper thinner than specified is used, paper jams may occur frequently at the registration section. In

this case, it is advisable to change (or reduce) the aligning amount.

However, if the aligning amount is reduced too much, this could cause the leading edge margin to vary

adversely. So, when adjusting the aligning amount, try to choose the appropriate amount while checking the

leading edge margin at the same time.