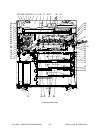

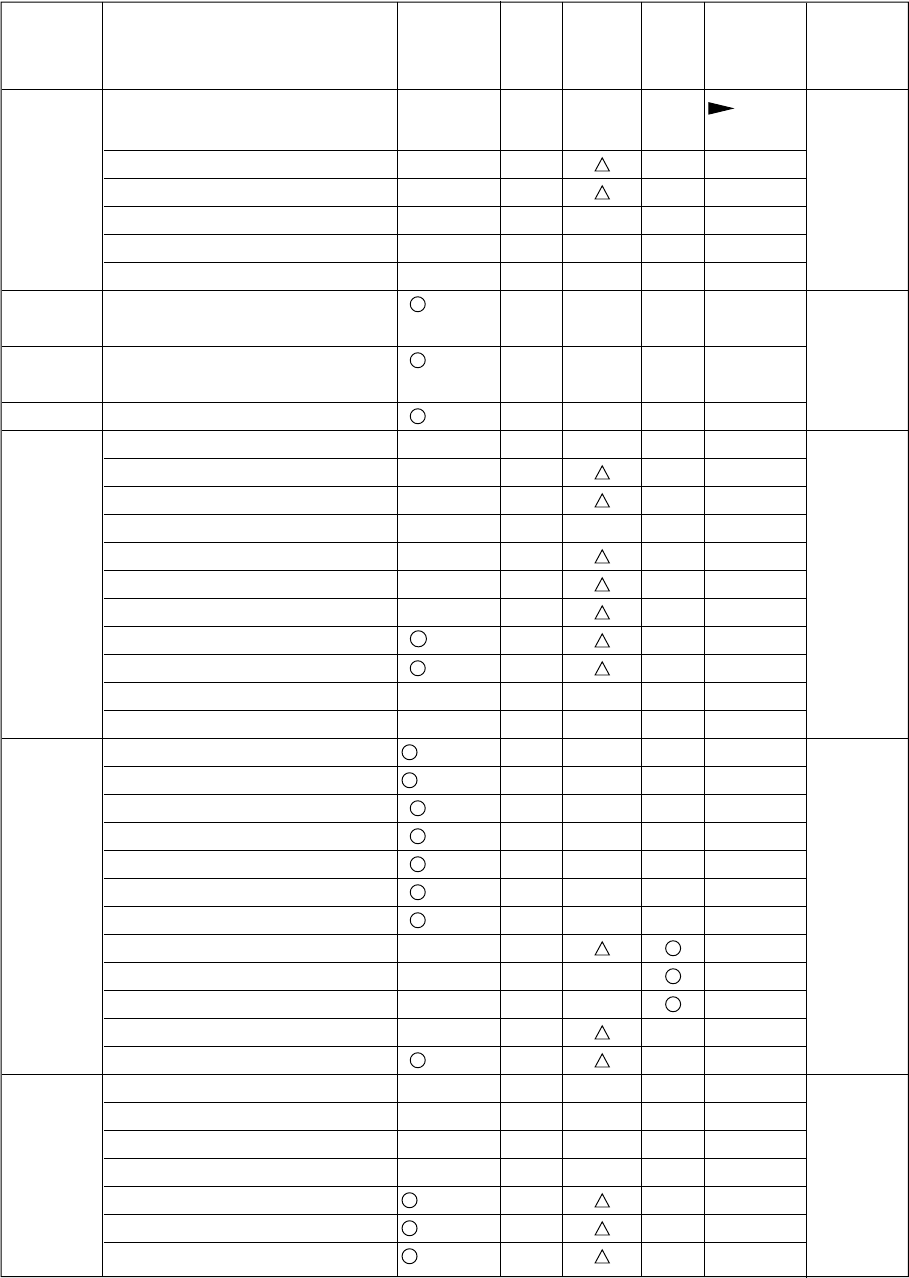

FC-210/310 PREVENTIVE MAINTENANCE 3- 4 February 2002 © TOSHIBA TEC

31.Cleaning roller 40/60 ch.3.6.7

<P28-I45>

32. Upper thermistors A (40/60) Fuser unit

Fuser unit 33. Lower thermistors A (40/60) counter

34. Fuser inlet guide A (40/60) (08-854)

35. Fuser exit guide A (40/60)

36. Paper exit roller A

Image quality

37. Image quality sensor’s area (40/60) *11

control Drum K

Color 38.Color registration sensor (40/60) life counter

registration (08-843)

Laser unit 39. Slit glass (40/60)

40. Pick-up roller A (40/60) 90 <P14-I13>

41. Feed roller A (40/60)

42. Separation roller A (40/60)

43. Bypass pick-up roller A (40/60) 90 <P17-I52>

Paper feeding

44. Bypass feed roller A (40/60)

system 45. Bypass separation roller A (40/60) —

46. Registration roller A (40/60)

47. Paper guide (40/60)

48. Paper dust removal brush (40/60)

49. Drive gears (tooth face) W

50. Registration unit support bushings W

51. Original glass

or A (40/60)

52. Platen cover

or A (40/60)

53.Mirror-1 (40/60)

54.Mirror-2 (40/60)

55.Mirror-3 (40/60)

Scanner 56. Reflector (40/60) —

57.Lens (40/60)

58. Exposure lamp

59.Original-width indicator

60. Automatic original detection unit

61. Slide sheet

62. Air filter (40/60)

63. Transfer belt 120/120 <P30-I2>

Transfer/ 64.Transfer roller (Y, M, C, K) 120/120 <P30-I22>

transport 65.Drive roller cleaning felt 120/120 <P30-I27> Transfer belt

unit 66. Transfer belt cleaning blade 120/120 <P30-I46> unit counter

(TBU) 67. Transfer belt recovery blade (120/120) (08-853)

68. Transfer belt drive roller (120/120)

69. Transfer belt driven roller (120/120)

Cleaning Lubri-

Replace- Opera-

Remarks Reference

Section Item to inspect

(X 1000) cation

ment tion

<P-I> counter

(X 1000) check