Functional Overview

10-8

HP DesignJet 5000 Series Printers Service Manual

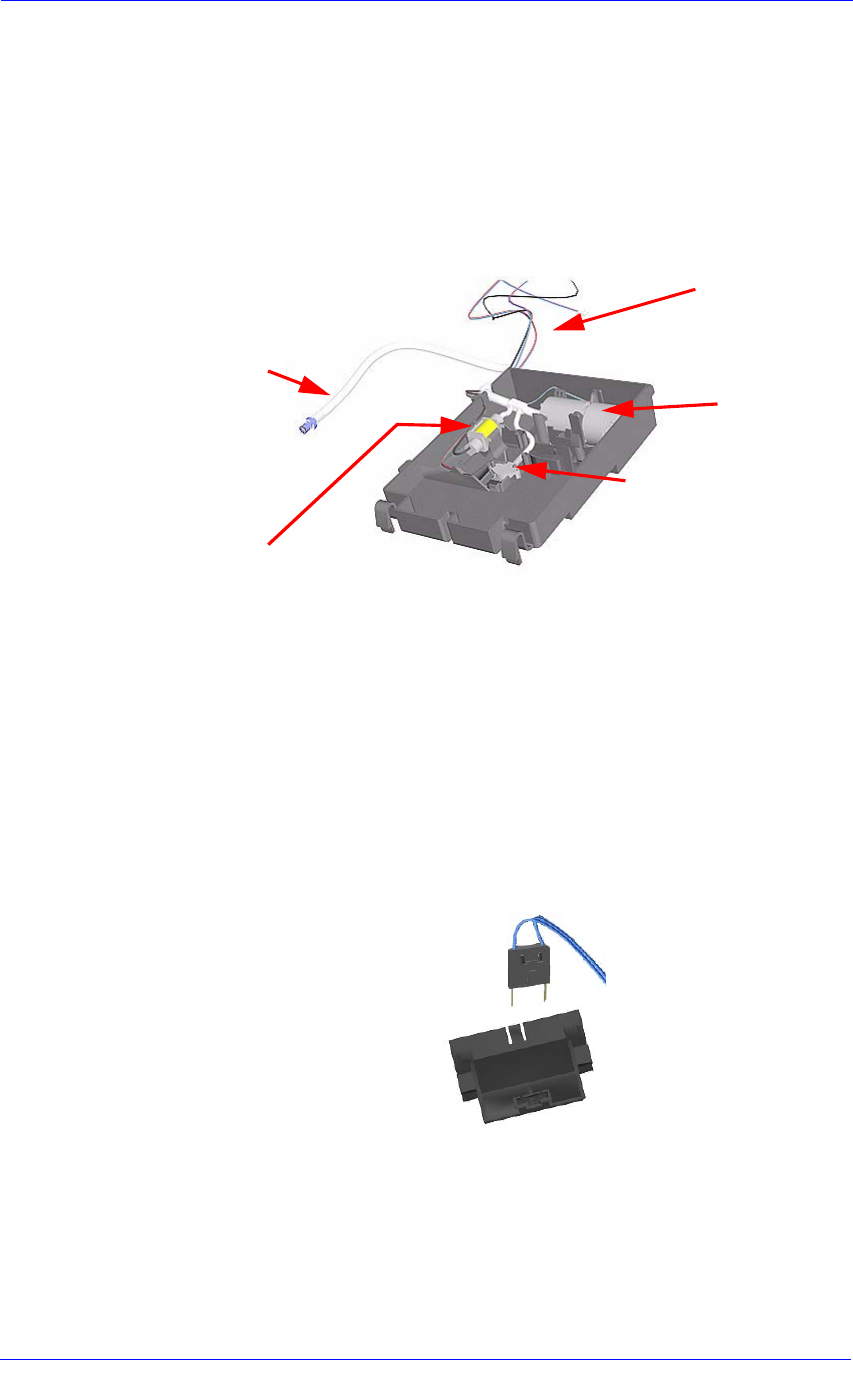

Air Pressurization System (APS)

The APS is the system that provides and controls the pressurization

of the ink in the Ink Cartridges and is located under the ISS. The key

purpose of this system is to ensure the minimum required ink

pressure at the inlet to each Printhead respectively at the required

print rates. The APS is also used to provide pressure for tube purge

and as part of the blow prime system operation.

The APS pressurizes the ink in the Ink Cartridge bags by

pressurizing the air around them. The Printer controls the air

pressure using the pump with feedback from the sensor; when

required the valve is opened to depressurize the air circuit. This

allows control of the ink pressure at the inlet to the Printheads.

Leak Detect System (LDS)

The purpose of the Leak Detect System (LDS) is to detect the

breakage of any of the Tubes that deliver ink from the Ink

Cartridges to the Printheads.

If a Tube breaks, as the system is pressurized, the ink flows through

the breakage and gets between the Tube and the Tube Carrier, and is

forced to go to the Ink Leak Detector where the leaking ink is

collected. There will be a potential short circuit between the two

metallic pins, and the ink leak will be detected.

Air Tube to Air

Connector and Ink

Cartridges

Cables to ISS PCA

DC motor-driven

air pump

Analog pressure

sensor

Two-way solenoid valve