123

[Connection and Setup of Position Control Mode]

Connection and Setup of

Position Control Mode

6A 0 to 100

<0>

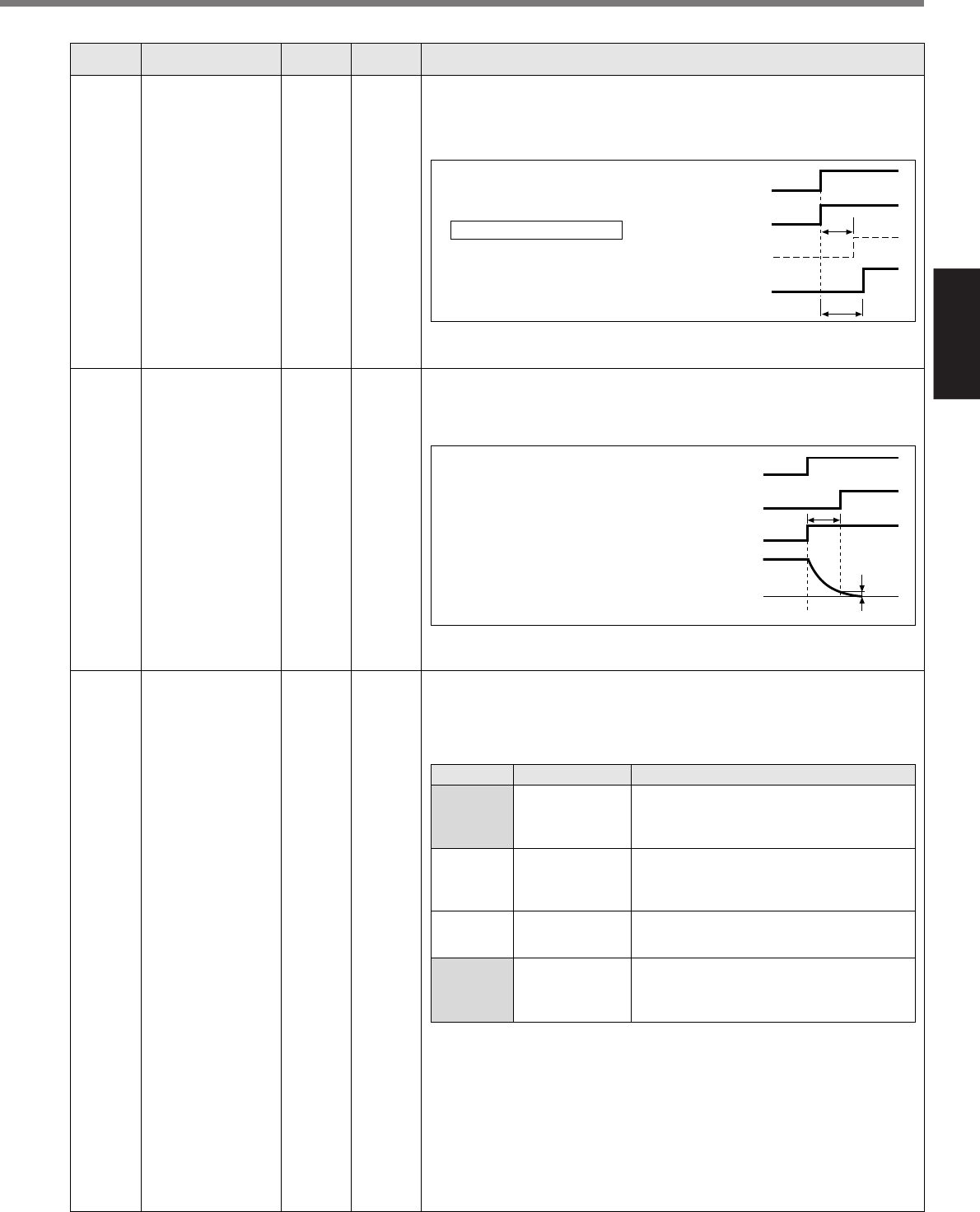

2msSetup of

mechanical brake

action at stalling

You can set up the time from when the brake release signal (BRK-OFF :

CN X5, Pin-10 and 11) turns off to when the motor is de-energized

(Servo-free), when the motor turns to Servo-OFF while the motor is at

stall.

Refer to P.44, "Timing Chart"-Servo-ON/OFF Action While the Motor Is at

Stall" of Preparation as well.

• Set up to prevent a micro-travel/

drop of the motor (work) due to the

action delay time (tb) of the brake

• After setting up Pr6a

>

=

tb ,

then compose the sequence so as

the driver turns to Servo-OFF after

the brake is actually activated.

ON

SRV-ON

BRK-OFF

actual brake

motor

energization

release

OFF

hold

release

energized

hold

non-

energized

Pr6A

tb

6B 0 to 100

<0>

2msSetup of

mechanical brake

action at running

You can set up time from when detecting the off of Servo-ON input signal

(SRV-ON : CN X5, Pin-29) is to when external brake release signal

(BRK-OFF : CN X5, Pin-10 and 11) turns off, while the motor turns to

servo off during the motor in motion.

Refer to P.45, "Timing Chart"-Servo-ON/OFF action while the motor is in

motion" of Preparation as well.

• Set up to prevent the brake

deterioration due to the motor

running.

• At Servo-OFF during the motor is

running, tb of the right fig. will be

a shorter one of either Pr6B

setup time, or time lapse till the

motor speed falls below 30r/min.

tb

ON

SRV-ON

BRK-OFF

motor

energization

release

OFF

hold

actual

brake

energized

non-

energized

30 r/min

6C

*

0 to 3

for

A, B-frame

<3>

for

C to F-frame

<0>

–Selection of

external

regenerative

resistor

With this parameter, you can select either to use the built-in regenerative

resistor of the driver, or to separate this built-in regenerative resistor and

externally install the regenerative resistor (between RB1 and RB2 of

Connector CN X2 in case of A to D-frame, between P and B2 of terminal

block in case of E, F-frame).

<Remarks>

Install an external protection such as thermal fuse when you use the

external regenerative resistor.

Otherwise, the regenerative resistor might be heated up abnormally and

result in burnout, regardless of validation or invalidation of regenerative

over-load protection.

<Caution>

When you use the built-in regenerative resistor, never to set up other

value than 0. Don't touch the external regenerative resistor.

External regenerative resistor gets very hot, and might cause burning.

Setup value

<0>

(C, D, E and

F-frame)

1

2

<3>

(A, B-frame)

Built-in resistor

External resistor

External resistor

No resistor

Regenerative processing circuit will be

activated and regenerative resistor overload

protection will be triggered according to the

built-in resistor (approx. 1% duty).

The driver trips due to regenerative overload

protection (Err18), when regenerative

processing circuit is activated and its active

ratio exceeds 10%,

Regenerative processing circuit is activated,

but no regenerative over-load protection is

triggered.

Both regenerative processing circuit and

regenerative protection are not activated, and

built-in capacitor handles all regenerative

power.

Standard default : < >

PrNo.

Setup

range

UnitTitle Function/Content

Regenerative resistor

to be used

Regenerative processing and

regenerative resistor overload