250

Damping Control

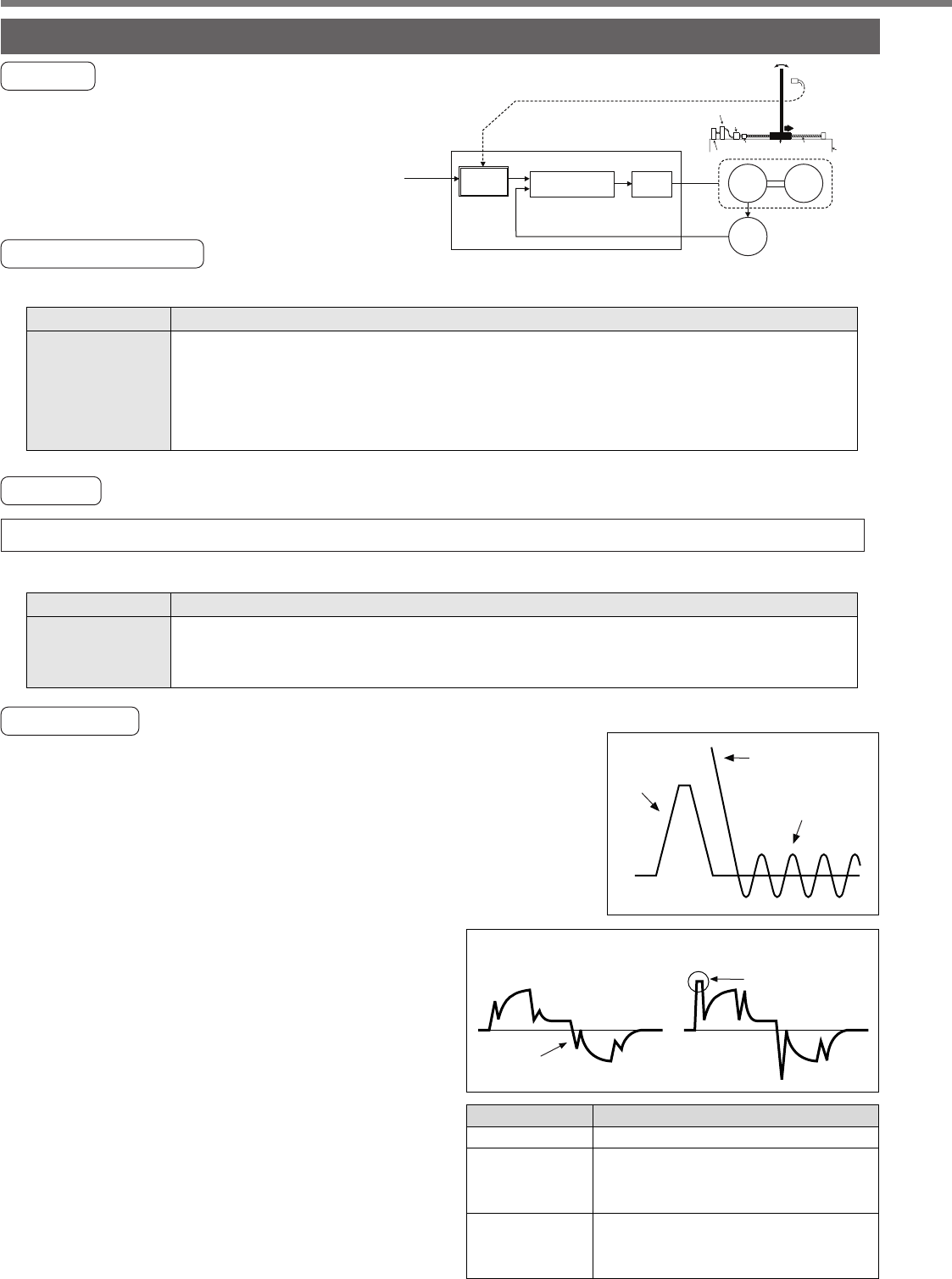

Outline

This function reduces the vibration by removing

the vibration frequency component from the

command when the load end of the machine

vibrates.

Applicable Range

This function can only be applicable when the following conditions are satisfied.

Caution

When you change the parameter setup or switch with VS-SEL, stop the action first then execute.

This function does not work properly or no effect is obtained under the following conditions.

How to Use

(1) Setup of damping frequency (1st : Pr2B, 2nd : Pr2D))

Measure the vibration frequency of the front edge of the machine.

When you use such instrument as laser displacement meter, and can

directly measure the load end vibration, read out the vibration fre-

quency from the measured waveform and enter it to Pr2B or Pr2D

(Damping frequency).

(2) Setup of damping filter (1st : Pr2C, 2nd : Pr2E))

First, set up 0.

You can reduce the settling time by setting up larger

value, however, the torque ripple increases at the

command changing point as the right fig. shows.

Setup within the range where no torque saturation

occurs under the actual condition. If torque satura-

tion occurs, damping control effect will be lost.

<Remark>

Limit the damping filter setup with the following formula.

10.0 [Hz] – Damping frequency

<

=

Damping filter setup

<

=

Damping frequency

(3) Setup of damping filter switching selection (Pr24)

You can switch the 1st or the 2nd damping filter de-

pending on the vibration condition of the machine.

Control mode

Conditions under which the damping control is activated

• Control mode to be either or both position control or/and full-closed control.

Pr02 = 0 : Position control

Pr02 = 3 : 1st control mode of position and velocity control

Pr02 = 4 : 1st control mode of position control and torque control

Pr02 = 6 : Full-closed control

Command

speed

Position deviation

Calculation of

vibration frequency

Torque

command

Torque saturation

Damping filter setup is

too large.

Damping filter setup is

appropriate.

Switching mode

No switching ( Both of 2 are valid.)

Switch with VS-SEL input.

Open : 1st damping filter

Close : 2nd damping filter

Switch with command direction.

CCW : 1st damping filter

CW : 2nd damping filter

Pr24

0

1

2

Servo driver

Motor position

Motor

Coupling

Ball

screw

Work

travel

Driver

PLC

Setup of front edge vibration

frequency

Motor

Encoder

Load

Position

command

Damping

filter

Position/Velocity

control

Torque

command

Current

control

Machine

base

Front edge vibrates.

Vibration

measurement

with

displacement

sensor

Motor

current

Load

Conditions which obstruct the damping control effect

• Vibration is triggered by other factors than command (such as disturbance).

• Ratio of resonance frequency and anti-resonance frequency is large.

• Vibration frequency is out of the range of 10.0-200.0 [Hz].

Manual Gain Tuning (Application)