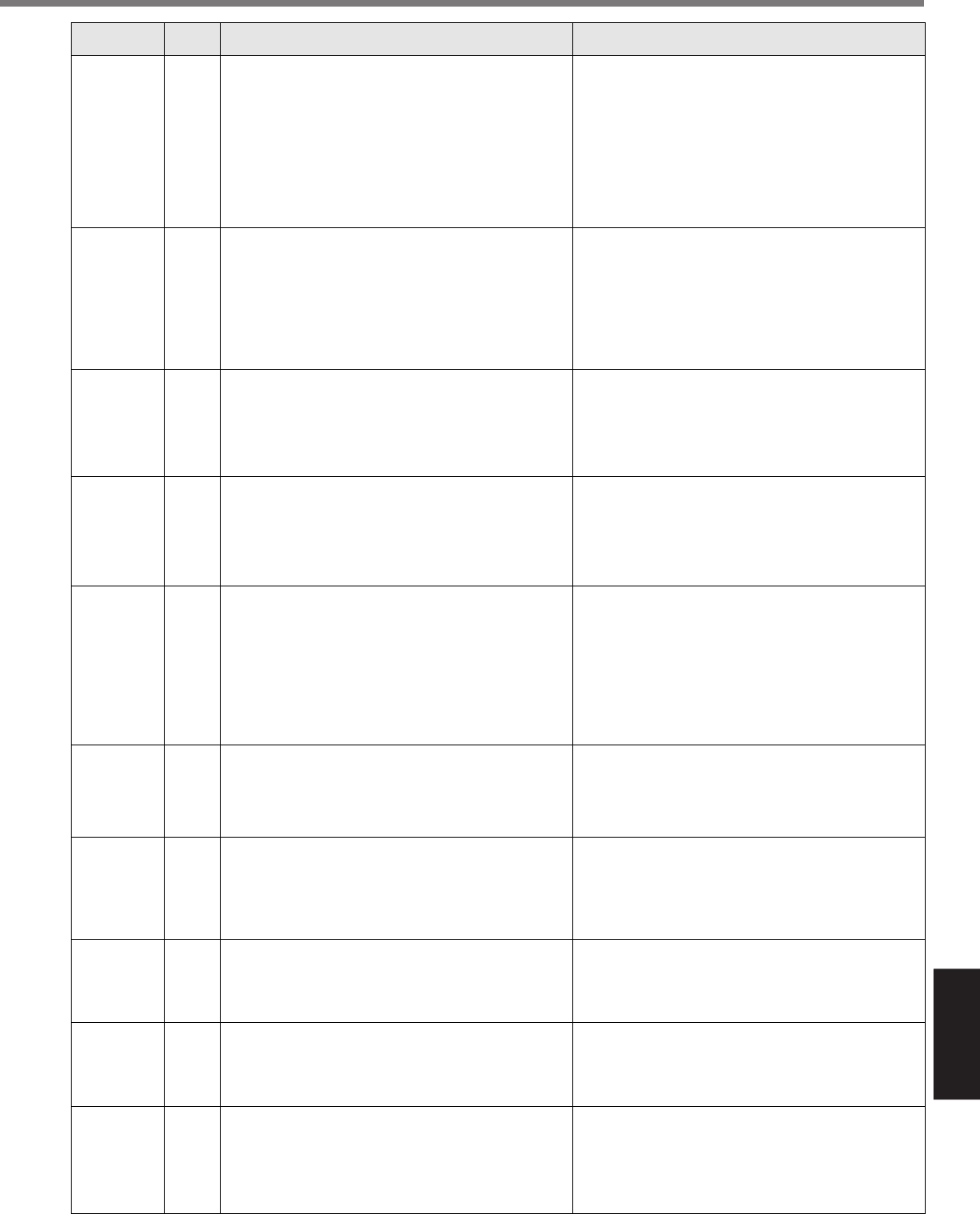

255

[When in Trouble]

When in Trouble

Protective

function

Causes Measures

Error

code No.

*Hybrid

deviation

excess

error

protection

25

Position of load by the external scale and position of

the motor by the encoder slips larger than the setup

pulses with Pr7B (Setup of hybrid deviation excess) at

full-closed control.

•

Check the connection between the motor and the load.

• Check the connection between the external scale and

the driver.

• Check that the variation of the motor position

(encoder feedback value) and the load position

(external scale feedback value) is the same sign

when you move the load.

Check that the numerator and denominator of the

external scale division (Pr78, 79 and 7A) and reversal

of external scale direction (Pr7C) are correctly set.

Over-speed

protection

26

The motor rotational speed has exceeded the setup

value of Pr73 (Over-speed level setup)

• Do not give an excessive speed command.

• Check the command pulse input frequency and divi-

sion/multiplication ratio.

• Make a gain adjustment when an overshoot has

occurred due to a poor gain adjustment.

• Make a wiring connection of the encoder as per the

wiring diagram.

• Set up Pr73 to 0 (Set up to motor max. speed x 1.2.)

Electronic

gear error

protection

27

Division and multiplication ratio which are set up with

the 1st and the 2nd numerator/denominator of the

electronic gear (Pr48 to 4B) are not appropriate.

• Check the setup values of Pr48 to 4B.

• Set up the division/multiplication ratio so that the

command pulse frequency after division.

multiplication may become less than 80Mpps at

deviation counter input portion, and 3Mpps at

command input portion.

*External

scale com-

munication

data error

protection

28

Communication error has occurred in data from the

encoder. Mainly data error due to noise. Encoder

cables are connected, but communication date has

some error.

• Secure the power supply for the encoder of DC5±5%

(4.75-5.25V)...pay attention especially when the

encoder cables are long.

• Separate the encoder cable and the motor cable if

they are bound together.

• Connect the shield to FG...refer to wiring diagram.

Deviation

counter

overflow

protection

29

34

Deviation counter value has exceeded 2

27

(134217728).

• Check that the motor runs as per the position com-

mand pulses.

• Check that the output toque has not saturated in

torque monitor.

• Make a gain adjustment.

• Set up maximum value to Pr5E (1st torque limit

setup) and Pr5F (2nd torque limit setup).

• Make a wiring connection of the encoder as per the

wiring diagram.

Software

limit

protection

The motor position has exceeded the range set with

software limit.

1)Gain has not matched up.

2)Setup value of Pr26 (Software limit setup) is small.

Refer to P.258,"Software Limit Function" before using

this.

1)Check the gain (balance of position loop gain and ve-

locity loop gain) and the inertia ratio.

2)Setup a larger value to Pr26.

35

*External

scale com-

munication

error

protection

Communication between the external scale and the

driver has been interrupted in certain times, and

disconnection detecting function has been triggered.

• Make a wiring connection of the external scale as per

the wiring diagram.

• Correct the miswiring of the connector pins.

36

*EEPROM

parameter

error

protection

Data in parameter storage area has been damaged

when reading the data from EEPROM at power-on.

• Set up all parameters again.

• If the error persists, replace the driver (it may be a

failure.) Return the product to the dealer or

manufacturer.

37

*EEPROM

check code

error

protection

Data for writing confirmation to EEPROM has been

damaged when reading the data from EEPROM at

power-on.

Replace the driver. (it may be a failure). Return the

product to a dealer or manufacturer.

38

Over-travel

inhibit

input

protection

Connection of both CW and CCW over-travel inhibit

input (CWL, Pin-8/CCW, Pin-9) to COM- have been

opened, while Pr04 (Over-travel inhibit input setup) is 0.

Or either one of the connection of CW or CCW over-

travel inhibit input to COM- has been opened, while

Pr04 is set to 2.

• Check that there are not any errors in switches, wires

or power supply which are connected to CW/CCW

over-travel inhibit input. Check that the rising time of

the control power supply (DC12-24V) is not slow.