359

[Supplement]

Supplement

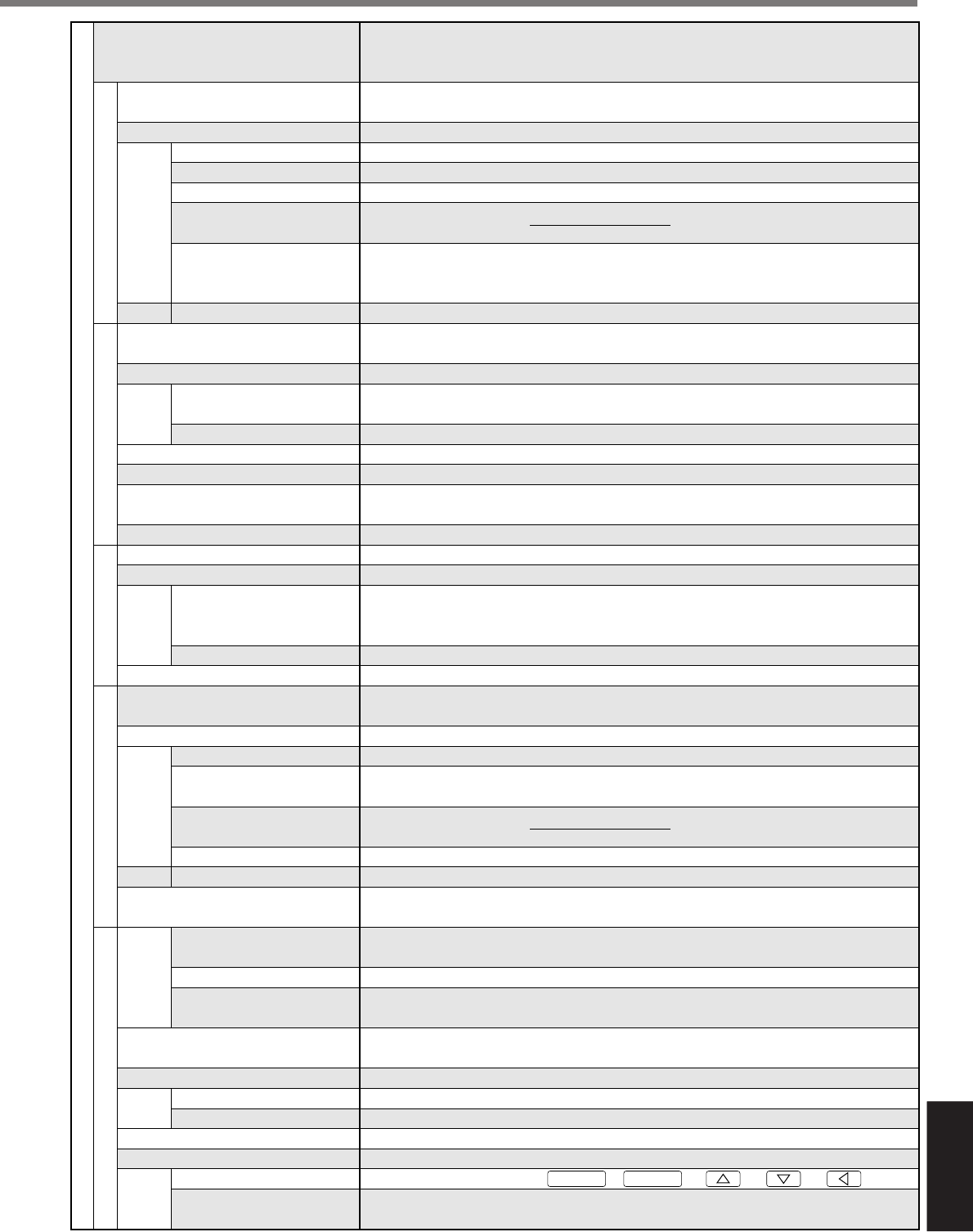

Function

Position control

Velocity controlTorque controlFull-closed controlCommon

Control input

Control input

Control output

Control input

Control output

Control input

Masking of unnecessary input

Division of encoder feedback pulse

Protective

function

Traceability of alarm data

Damping control function

Setup range of division/multiplication of

external scale

Control output

Speed control range

Internal velocity command

Soft-start/down function

Zero-speed clam

Control input

Control output

Speed limit function

Analog

input

Analog

input

Max. command pulse frequency

Input pulse signal format

Type of input pulse

Electronic gear (Division/

Multiplication of command pulse)

Electronic gear (Division/

Multiplication of command pulse)

Smoothing filter

Velocity command input

Torque limit command input

Velocity command input

Max. command pulse frequency

Real-time

Normal mode

Manual

Setup support software

Fit-gain function

Soft error

Hard error

Input pulse signal format

Smoothing filter

Torque limit command input

Speed limit input

Torque limit command input

Pulse

input

Pulse

input

Auto-gain

tuning

Setup

Analog

input

Analog

input

as a position command input

x

(1 to 10000) x 2

(0 to 17)

Process the command

pulse frequency

1 to 10000

as a position command input

x

(1 to 10000) x 2

(0 to 17)

Process the command

pulse frequency

1 to 10000

Inputs of 1) Servo-ON, 2) Alarm clear, 3) Gain switching, 4) Control mode switching,

5) CW over-travel inhibition and 7) CCW over-travel inhibition are common,

and other inputs vary depending on the control mode.

(1) Deviation counter clear, (2) Command pulse inhibition, (3) Damping control switching,

(4) Gain switching or Torque limit switching

Positioning complete (In-position)

Exclusive interface for line driver : 2Mpps, Line driver : 500kpps, Open collector : 200kpps

Support (1) RS422 line drive signal and (2) Open collector signal from controller.

(1) CW/CCW pulse, (2) Pulse signal/rotational direction signal, (3) 90˚C phase difference signal

Primary delay filter is adaptable to the command input

Selectable of (1) Position control for high stiffness machine and

(2) FIR type filter for position control for low stiffness machine.

Individual torque limit for both CW and CCW direction is enabled. (3V/rated torque)

(1) Speed zero clamp, (2) Selection of internal velocity setup,

(3) Gain switching or Torque limit switching input

(1) Speed arrival (at-speed)

Setup of scale and rotational direction of the motor against the command voltage is enabled with

parameter, with the permissible max. voltage input = Å} 10V and 6V/rated speed (default setup).

Individual torque limit for both CW and CCW direction is enabled. (3V/rated torque)

1 : 5000

8-speed with parameter setup

Individual setup of acceleration and deceleration is enabled, with 0 to 10s/1000r/min. Sigmoid

acceleration/deceleration is also enabled.

0-clamp of internal velocity command with speed zero clamp input is enabled.

(1) CW over-travel inhibition, (2) CCW over-travel inhibition, (3) Speed zero clamp

(1) Speed arrival (at-speed)

Setup of scale and CW/CCW torque generating direction of the motor against the command

voltage is enabled with parameter, with the permissible max. voltage input = Å} 10V and

3V/rated speed (default setup).

Speed limit input by analog voltage is enabled. Scale setup with parameter.

Speed limit value with parameter or analog input is enabled.

(1) CW over-travel inhibition, (2) CCW over-travel inhibition (3) Deviation counter clear, (4)

Command pulse input inhibition, (5) Electronic gear switching, (6) Damping control switching

(1) Full-closed positioning complete (in-position)

500kpps (photo-coupler input), 2Mpps (Exclusive input for line driver)

Differential input. Selectable with parameter ((1) CCW/CW, (2) A and B-phase, (3) Command

and direction

Primary delay filter is adaptable to the command input.

Individual torque limit for both CW and CCW direction is enabled. (3V/rated torque)

Setting of ratio between encoder pulse (denominator) and external scale pulse (numerator) is

enabled within a range of (1 to 10000) x 2

(0 – 17)

/ (1 to 10000).

Corresponds to load inertia fluctuation, possible to automatically set up parameters related to

notch filter.

Estimates load inertia and sets up an appropriate servo gain.

Automatically searches and sets up the value which makes the fastest settling time with

external command input.

Masking of the following input signal is enabled.

(1) Over-travel inhibition, (2) Torque limit, (3) Command pulse inhibition, (4) Speed-zero clamp

Set up of any value is enabled (encoder pulses count is the max.).

Over-voltage, under-voltage, over-speed over-load, over-heat, over-current and encoder error etc.

Excess position deviation, command pulse division error, EEPROM error etc.

Traceable up to past 14 alarms including the present one.

Manual setup with parameter

5push switches on front panel

PANATERM

®

(Supporting OS : Windows95, Windows98, Windows ME, Windows2000,

Windows.NET and Windows XP)

MODE SET