237

[Adjustment]

Adjustment

Auto-Gain Tuning Action

(1) In the normal mode auto-gain tuning, you can set up the response with machine stiffness No..

Machine stiffness No.

•

Represents the degree of machine stiffness of the customer's machine and have values from o to 15.

You can set a higher No. to the high stiffness machine and set up a higher gain.

• Usually start setting up with a lower value and increase gradually to repeat auto-gain tuning in the

range where no oscillation, no abnormal noise, nor vibration occurs.

(2) This tuning repeats max. 5 cycles of the action pattern set with Pr25 (Normal mode auto-gain tuning

action). Action acceleration will be doubled every one cycle after third cycle. Tuning may finish, or action

acceleration does not vary before 5th cycle depending on the load, however, this is nor an error.

How to Operate

(1) Set up the action pattern with Pr25.

(2) Shift the load to the position where no hazard is expected even though the action pattern which is set

with Pr25 is executed.

(3) Prohibit the command entry.

(4) Turn to Servo-ON.

(5) Start up the auto-gain tuning.

Use the front panel or the "PANATERM

®

".

For the operation of the front panel, refer to P.71, "Auto-Gain Tuning Mode" of Preparation.

(6) Adjust the machine stiffness to the level at which no vibration occurs and obtain the required response.

(7) Write the result to EEPROM, if it is satisfactory.

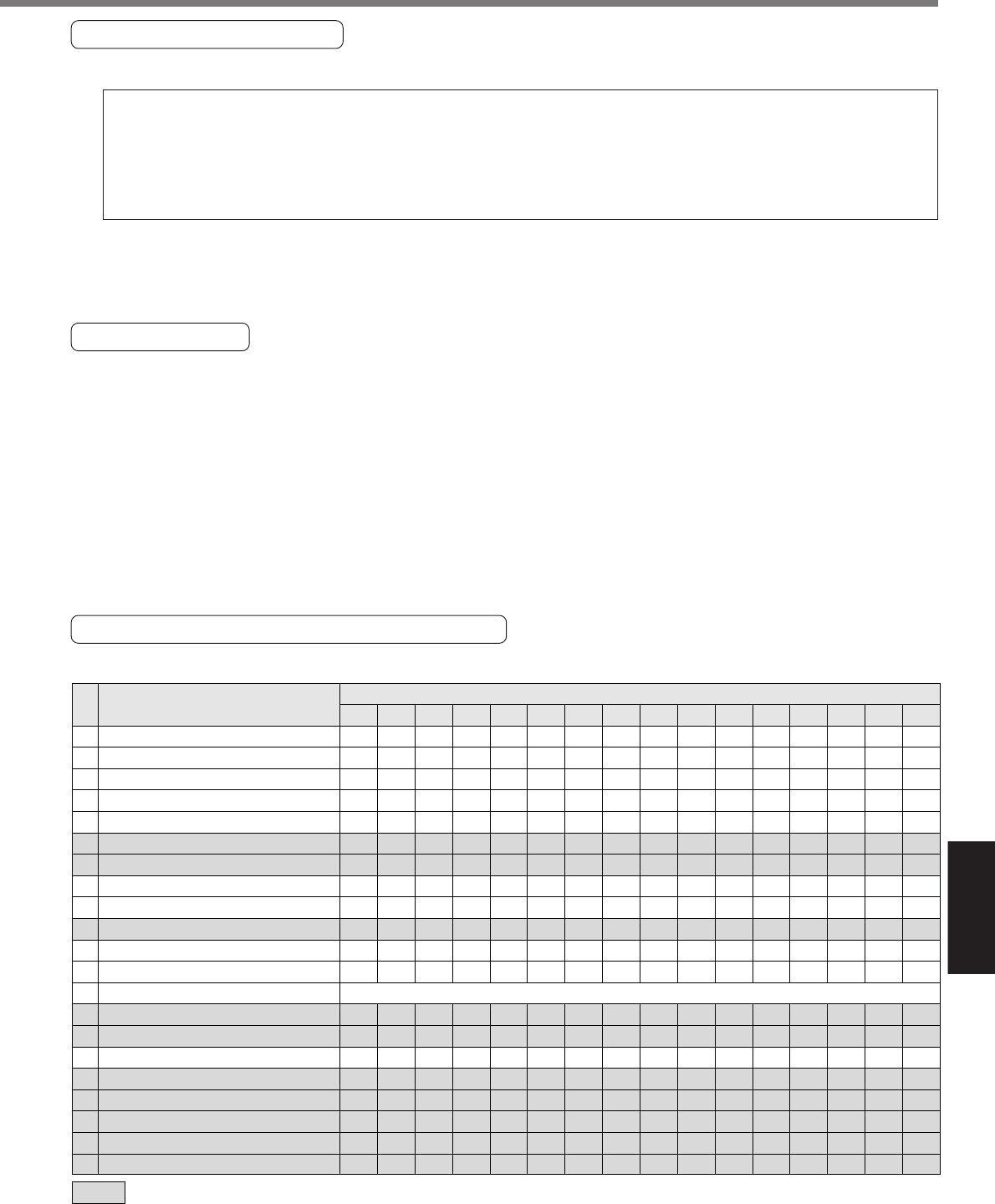

Parameters Which Are Automatically Set

Table of auto-gain tuning

10 1st gain of position loop

11 1st gain of velocity loop

12

1st time constant of velocity loop integration

13 1st filter of velocity detection

14

1st time constant of torque filter time *2

15 Velocity feed forward

16 Velocity FF filter

18 2nd gain of position loop

19 2nd gain of velocity loop

1A

2nd time constant of velocity loop integration

1B 2nd filter of speed detection

1C

2nd time constant of torque filter

*

2

20 Inertia ratio

27

Setup of instantaneous velocity observer

30 2nd gain setup

31 1st mode of control switching

*

1

32 1st delay time of control switching

33 1st level of control switching

34 1st Hysteresis of control switching

35 Switching time of position gain

36 2nd mode of control switching

0

[1]

2

3 [4]

5

6

7

8

9

10 11 12 13

14

15

12

9

62

0

253

300

50

19

9

999

0

253

0

1

10

30

50

33

20

0

32

18

31

0

126

300

50

38

18

999

0

126

0

1

10

30

50

33

20

0

39

22

25

0

103

300

50

46

22

999

0

103

0

1

10

30

50

33

20

0

48

27

21

0

84

300

50

57

27

999

0

84

0

1

10

30

50

33

20

0

63

35

16

0

65

300

50

73

35

999

0

65

0

1

10

30

50

33

20

0

72

40

14

0

57

300

50

84

40

999

0

57

0

1

10

30

50

33

20

0

90

50

12

0

45

300

50

105

50

999

0

45

0

1

10

30

50

33

20

0

108

60

11

0

38

300

50

126

60

999

0

38

0

1

10

30

50

33

20

0

135

75

9

0

30

300

50

157

75

999

0

30

0

1

10

30

50

33

20

0

162

90

8

0

25

300

50

188

90

999

0

25

0

1

10

30

50

33

20

0

206

115

7

0

20

300

50

241

115

999

0

20

0

1

10

30

50

33

20

0

251

140

6

0

16

300

50

293

140

999

0

16

0

1

10

30

50

33

20

0

305

170

5

0

13

300

50

356

170

999

0

13

0

1

10

30

50

33

20

0

377

210

4

0

11

300

50

440

210

999

0

11

0

1

10

30

50

33

20

0

449

250

4

0

10

300

50

524

250

999

0

10

0

1

10

30

50

33

20

0

557

310

3

0

10

300

50

649

310

999

0

10

0

1

10

30

50

33

20

0

Stiffness value

represents parameters with fixed value. Default for A to C-frame is 4, and 1 for D to F-frame.

*1 Stiffness value is 10 for position control and full-closed control, and 0 for velocity control and torque control.

*2 Lower limit for stiffness value is 10 for 17-bit encoder, and 25 for 2500P/r encoder.

Title

Pr

No.

Estimated load inertia ratio