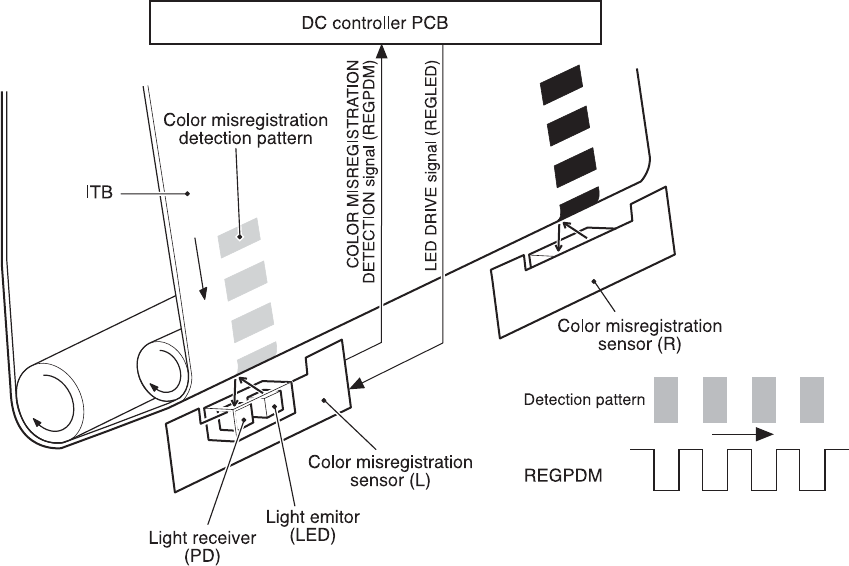

The DC controller monitors the color misregistration sensors (PS12) during the foregoing

color misregistration control. There are two units of PS12 on the ITB, each having one light

emitter (LED) and one light receiver (PD).

The following is the sequence of this control.

1. The DC controller sends LED DRIVE signal (REGLED) and lets the LED emit light.

2. The light of the LED is reflected off the ITB and received by the PD on the sensor. The

light amounts received at the PD differ depending on whether or not the light is reflected

from the area the toner is on.

3. The light receiver converts the received light amount to voltage and sends it to the DC

controller in the form of the COLOR MISREGISTRATION DETECTION signal

(REGPDM).

4. The DC controller detects the positions of the detection patterns according to the time

the REGPDM signals vary.

Figure 5-54.

Color misregistration detection

The DC controller notifies the formatter of each error when the following errors are found

during color misregistration detection. The initial value is reset to the new color

misregistration adjustment value whenever an error occurs.

● Color misregistration sensor abnormality warning: No light is received at the light

receivers.

● Color misregistration measurement out of range warning: The measurement is found to

be out of specified range.

Image stabilization control

This controls the variation of the image density caused by an environmental change or

deterioration of the photosensitive drum, toner, etc.

ENWW Image formation system 177