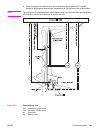

Media detection

This printer detects the media type to prevent a fuser defect.

The DC controller controls the media sensor (PS5) for this detection.

The PS5 has a light emitter (LED) and a light receiver (CMOS sensor). The light from the

emitter is reflected off the media surface and received at the receiver.

The DC controller turns on the PS5 when a fed sheet passes through the registration roller,

then detects the roughness of media surface according to the patterns (luminance

distribution within a specified area) of the detected light by the CMOS sensor. Based on the

detected roughness, the DC controller identifies the media type (normal paper, gloss paper,

gloss film, or OHT) and sends the media type to the formatter.

The DC controller changes the paper feed speed according to the detected media type,

when the detected media does not match the selected print mode. (See

Feed speed control,

earlier in this chapter, for feed speed change.)

Figure 5-61.

Media detection

Fuser/delivery unit

The fuser/delivery unit, being comprised of the fuser and the delivery unit, feeds paper from

the fuser to a delivery tray (either the face-up tray or the face-down tray).

The available tray is switched as the face-up tray opens and closes. Open the face-up tray

for face-up delivery, and close the tray for face-down delivery.

The following is the sequence of paper feed at the fuser/delivery unit.

1. The paper after the secondary transfer is fed into the fuser.

ENWW Pickup/feed system 189