e-STUDIO3511/4511 IMAGE QUALITY CONTROL 15 - 2 November 2003 © TOSHIBA TEC

15

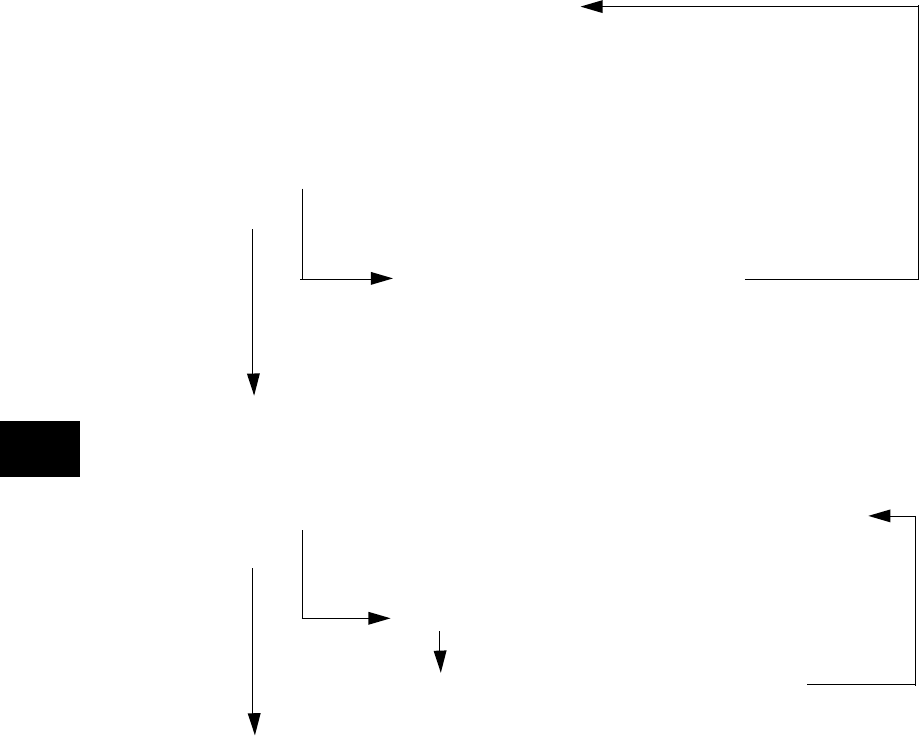

15.3 Flow Chart of Control Procedure

Start of control procedure (when meeting the image quality control starting conditions such as power-ON)

[1] The surface potential of photoconductive drum is estimated with the drum thermistor and tempera-

ture/humidity sensor.

[2] Reference image forming conditions are set.

[3] The sensor light source is adjusted.

[4] The test pattern is formed on the transfer belt.

[5] Toner adhesion amount of test pattern (high density) is calculated.

[6] Judgment

(whether the toner adhesion amount of the test pattern is within the acceptable

range or not)

NO

Modifies the image forming conditions.

YES

[7] Toner adhesion amount of the test pattern (low density) is calculated.

[8] Judgment

(whether the toner adhesion amount of the test pattern is within the acceptable

range or not)

NO Return to [8].

Modifies the image forming conditions.

YES

The test pattern is formed on the transfer belt.

[9] The image forming conditions are determined and stored in NVRAM.

[10] Control procedure is completed.

(The determined image forming conditions will be reflected on subsequent copies.)

Return to [4].

→→→→→

→→