November 2003 © TOSHIBA TEC 3 - 11 e-STUDIO3511/4511 COPY PROCESS

3

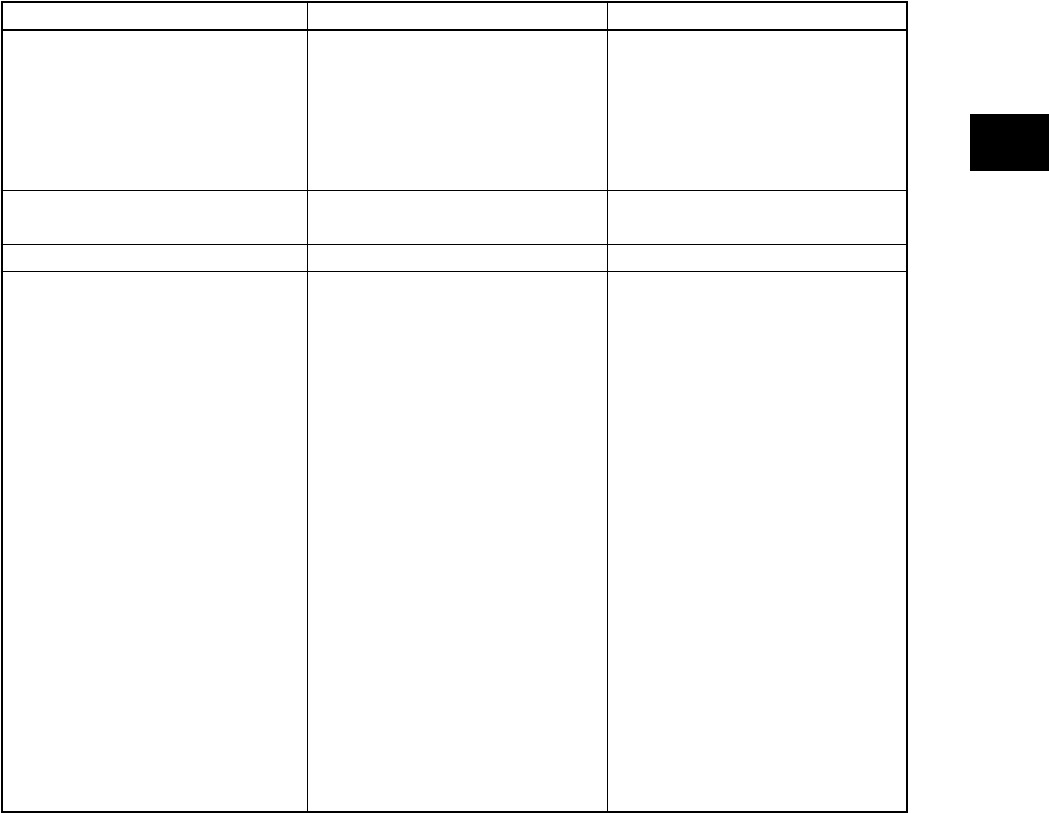

8. Photoconductive drum cleaning

(1) Method

(2) Recovered toner

(3) Transfer charge removal

9. Transfer belt cleaning

10.Discharge

11.Fusing

(1) Method

(2) Cleaning

(3) Heat roller temperature

(4) Heater

(1) Blade cleaning

(2) Non-reusable

(3) Simultaneous cleaning and

discharging by the conductive

blade

-

LED array (red)

(1) Belt fusing system

• Upper heat roller: Fluorinated

aluminum roller (ø30)

(Lamp rating: 550W)

• Fuser roller: Silicon sponge

roller (ø38)

• Lower heat roller: PFA tube

roller (ø40)

(Lamp rating: 450 W)

• Fuser belt: PFA tube belt (ø70)

(2) Oil roller method

• Oil roller (ø22)

• Cleaning roller (ø21)

(3) ON/OFF control by thermistor

(upper/lower roller independent

temperature control)

(4) Halogen lamp

(1) Same as FC-210/310

(2) Same as FC-210/310

(3) Same as FC-210/310

Blade cleaning

(contact/release mechanism)

Same as FC-210/310

(1) Belt fusing system

• Fuser roller : Fluorinated iron

roller (ø40)

(IH coil: 700 -1300W)

• Pressure roller: Silicon sponge

roller (Surface - PFA tube)

• Fuser belt: PFA tube belt (ø60)

• Separation roller: Ceramic

roller (ø20)

(2) Oil roller method

• Oil roller (ø18)

• Cleaning roller (ø16)

(3) ON/OFF control and power

control by thermistor

(4) IH coil

Process FC-210/310 e-STUDIO3511/4511