e-STUDIO3511/4511 COPY PROCESS 3 - 6 November 2003 © TOSHIBA TEC

3

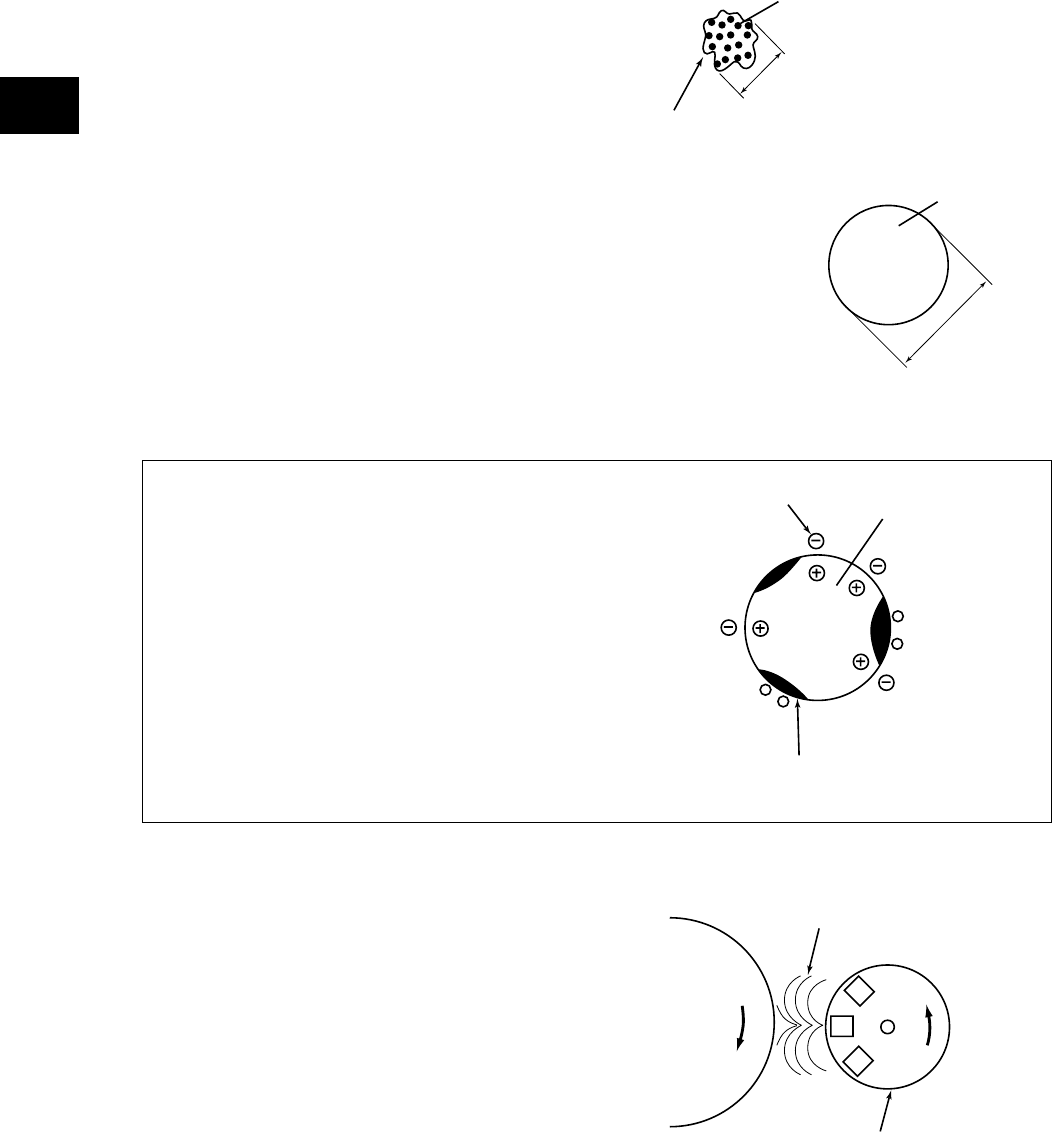

• About developer material

The developer material is comprised of a mixture

of toner and carrier. The toner is charged to a

negative polarity and the carrier to a positive

polarity, due to the friction with each other

caused by mixing.

Toner :Mainly consists of resin and coloring.

Carrier: Consists of ferrite, and over its surface

resin coating to provide consistent frictional

electrification.

N

S

S

[Toner]

Ferrite

[Carrier]

Note:

If the developer material is used for a long period

of time (beyond its normal life span), toner will

become caked onto the carrier.

The performance of the carrier is lowered.

Result: 1. Image density is lowered.

2. Toner scattering occurs.

3. Background fogging occurs.

Solution: Replace the developer material.

Toner

Carrier

Where toner is caked, no

frictional electrification

occurs.

• Magnetic roller

- Magnetic brush development technique -

Inside magnetic rollers, the south and north poles

are arranged as shown in the right figure. The

developer material forms a brush-like fluff which

contacts the photoconductive drum surface.

This is caused by the lines of magnetic force

between the south and north poles.

Lines of magnetic force

Magnetic roller

Photoconductive

drum

Fig. 3-309

Fig. 3-310

Fig. 3-311

→

→

Coloring agent

(5-10%)

5-13µm

Resin (90-95%)

30-100µm