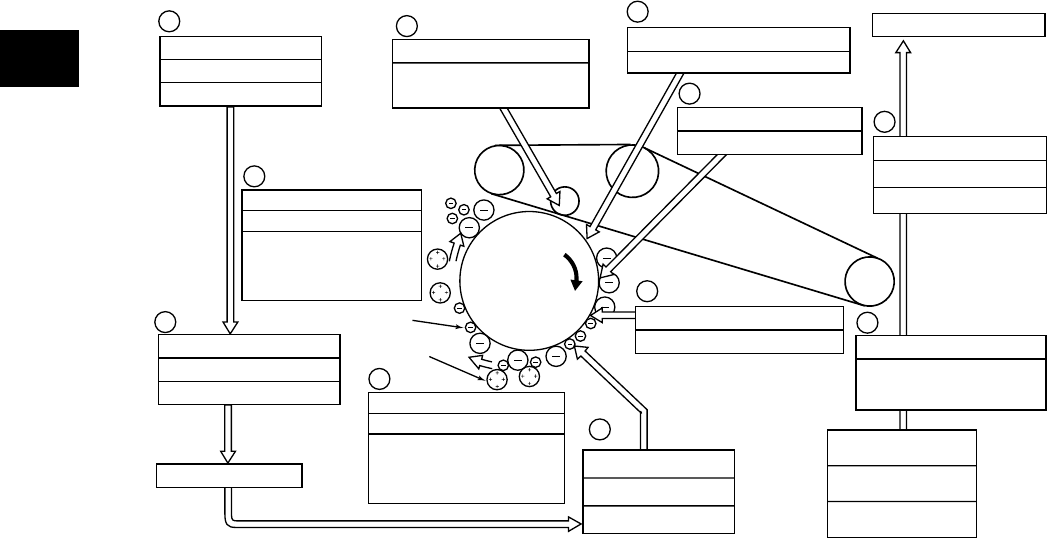

e-STUDIO3511/4511 COPY PROCESS 3 - 2 November 2003 © TOSHIBA TEC

3

2

3

7

4

5-2

8

5-1

1

9

10

6

Original exposure

Xenon lamp

16 W

Data reading (scanning)

CCD

600dpi, 7450 pixels

Image processing

Data writing

Semiconductor laser

Pw=4.0 nJ/mm

2

Discharging (LED array)

Wavelength 660nm x 14pcs.

Charger (grid voltage)

Cleaning

-1000 V

Fusing

IH coil

700 to 1300 W

Paper exit

2nd transfer

(+)1000V (500 to 4800V)

(-)-1000V (-100 to –2000V)

Bypass feeding

PFP/LCF feeding

Drawer feeding

Color development

Magnetic roller bias

-400V (-100 to -900V) DC

1.0 kV/10kHz AC

Carrier

Toner

3.2 General Description of Copying Process

1. Charging: Places a negative charge on the

surface of the photoconductive drum.

↓

2. Original exposure: Converts images on the

original into optical signals.

↓

3. Data reading: The optical image signals are

read into CCD and converted into electrical

signals.

↓

4. Data writing: The electrical image signals are

changed to light signals (by laser emission)

which expose the surface of the

photoconductive drum.

↓

5. Development: Negatively-charged toner is

made to adhere to the photoconductive drum,

producing a visible image.

↓

6. 1st transfer: Transfers the visible image

(toner) on photoconductive drum to the

transfer belt.

↓

7. 2nd transfer: Transfers the visible image

(toner) on the transfer belt to paper.

↓

8. Fusing: Fuses the toner image to the paper

by applying heat and pressure.

↓

9. Blade cleaning : While scraping off the

residual toner from the drum by the blade,

this blade also eliminates the (+) residual

charge on the drum left after image transfer.

↓

10. Discharging: Eliminates the residual (–)

charge from the surface of the

photoconductive drum.

Photocon-

ductive drum

1800V (400 to 4000V)

1st transfer

Black development

Magnetic roller bias

-400V (-100 to -900V) DC

1.2 kV/10kHz AC

-600V (-300 to -1200V)

Fig. 3-201

04/01