Troubleshooting

Component-level Troubleshooting

5

5-43

logic high by measuring U15 pin 5. If the signal is incorrect, the control line WB

ON/OFF* from the Wideband Output (A5) assembly is probably at fault. If the

control line is correct check U15A and associated components.

Note

The input CLK and CLK* is a low-level (400 mV p-p) signal generated by

the Regulator/Guard Crossing assembly.

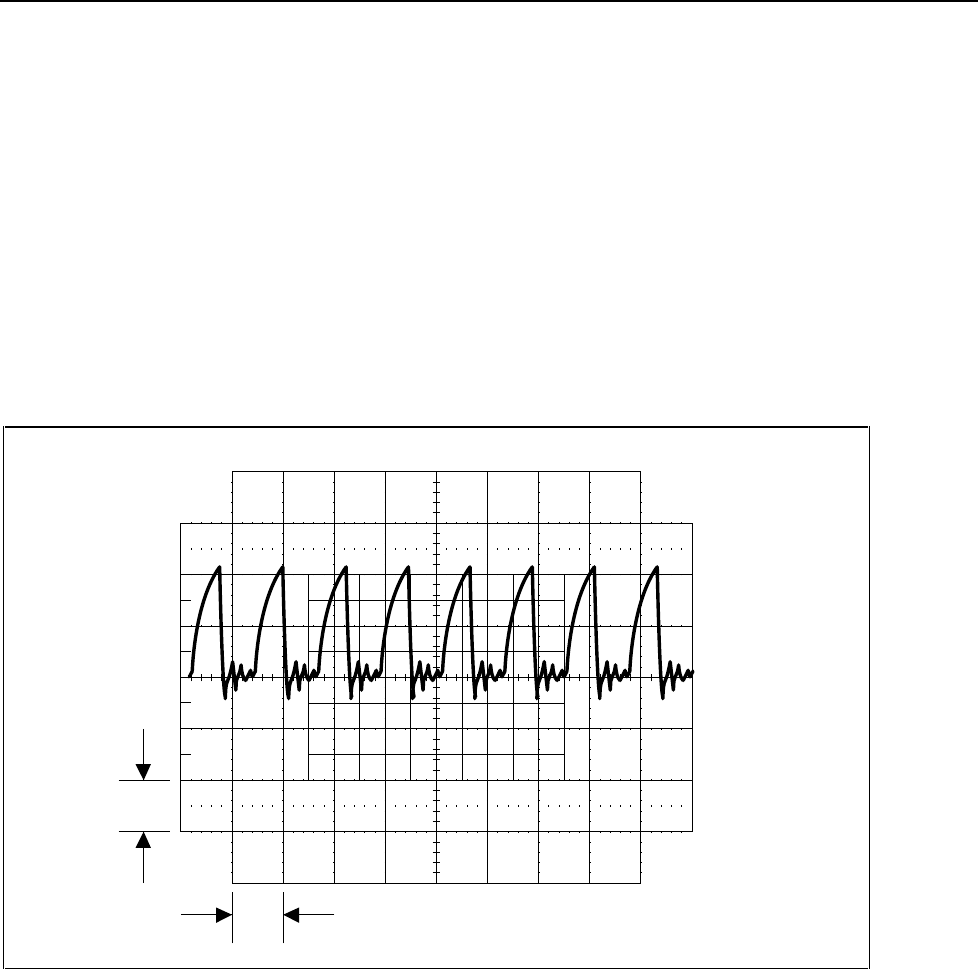

4. Check the 4 MHz to 8 MHz feedback signal. Set the Calibrator to 1V at 1.2 MHz,

operate. Connect an oscilloscope to TP15 and verify it displays a 4.8 MHz signal

similar to that shown in Figure 5-3. Use a frequency counter and verify that the

frequency of this signal is 4.8 MHz ±0.01%. If a failure is detected, continue with

step 5; otherwise skip to step 10.

1 V

10 ms

F5-2.EPS

Figure 5-2. Waveform at TP1

5. Check the VCO Supply Voltage. Set the Calibrator to 1V at 1.2 MHz, operate. Using

a DMM measure the dc voltage at U3 pin 8 and verify it is -5V ±7%. If a failure is

detected, check Q2, Q3, U7, and associated components.

6. Check the VCO circuit. Power down the Calibrator, remove shorting header E6 from

the J6 pins, and connect an external variable dc reference(2V to 13V) to TP2. Power

up the Calibrator and set it for 1V at 1.2 Mhz, operate. Connect a frequency counter

to TP3. Vary the external dc reference from 2 to 12V and verify the frequency

counter reading changes from approximately 32 to 64 MHz. If a failure is detected,

check the VCO circuit containing U3, CR1, CR2, and associated components.

7. Check the dividers in U4 and U5. Power down the Calibrator, remove shorting

header E6 from the J6 pins, and connect an external variable dc reference (2 to 13V)

to TP2. Power up the Calibrator and set it for 1V at 1.2 MHz, operate. Connect a