5700A/5720A Series II Calibrator

Service Manual

1-10

COST $

COST $

CALIBRATION CYCLE

CALIBRATION CYCLE

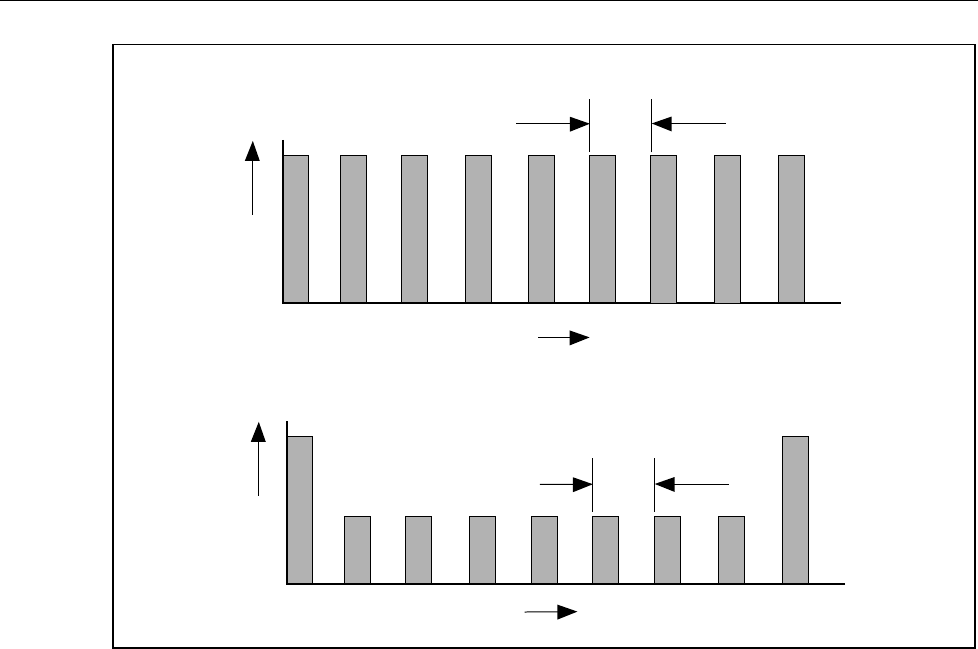

TRADITIONAL CALIBRATOR CALIBRATION

5700A/5720A SERIES II CALIBRATION

TIME

TIME

f1-1.eps

Figure 1-1. Time and Costs: Calibrator Calibration

1-17. The Calibration Process

Calibration requires only three external standards: 10V, 1Ω, and 10 kΩ.

Environmentally-controlled internal check standards provide the primary reference

points. A stored table of calibration constants defines additional reference points for

controlling the output. Traceable calibration and adjustment to the specified level of

performance is accomplished in a semi-automated process that revises this table.

When you finish calibration, but before you save the new constants, the calibrator

presents you with the proposed adjustments as +/- ppm of range and percentage change

in specification for each range and function. You can print a list of changes through the

serial (RS-232C) port, or send them to a computer through either the serial port or the

IEEE-488 port. Also on completion of calibration, the calibrator displays the largest

proposed change.

Calibration can be completed as far as deriving and printing the proposed adjustments

without changing the setting of the rear panel CALIBRATION switch; however, the

switch must be set to ENABLE to store the changes in nonvolatile memory and make

them effective. The switch is recessed to allow the metrologist to cover it with a

calibration sticker to guarantee calibrator integrity.

1-18. Establishing Traceability

Traceability to national standards is established as follows: