9. Quick Open Function

------------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------

9 - 2

9.1 FUNCTION SUMMARY

OUTLINE

In case of teaching a work program of arc welding, it is required to set a detailed

arc exclusive function such as weaving, Retry/Restart and welding machine's

characteristic as well as welding relating condition such as voltage and current. And

there's also several cases to need to check the step or auxiliary point's position

basically. The conditions related with arc welding are managed as files inner controller,

so there are needs to have functions to edit these condition files in easy and quick

way. Because of these reasons, Quick Open function can be an answer that can check and

change in controlling the key just once.

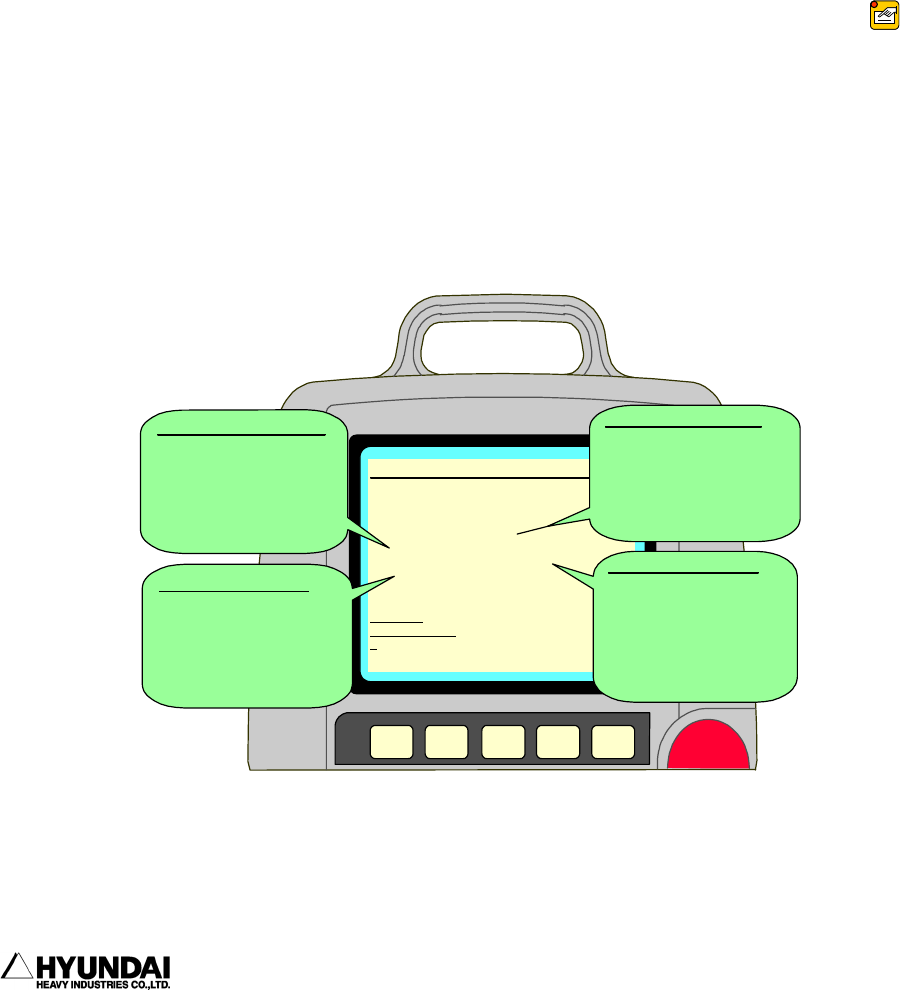

If taking a welding start condition for an example, if pressing [Quick Open] key(

)

when cursor is on the ARCON instruction statement which is used for Arc On, condition

number's contents in welding start condition are displayed using in present instruction

statement, and you can check and change the contents detailed in this screen. As well,

if there is an other condition file related with present condition file, it's possible

to move immediately. In other words, it is function that check and change the relating

contents detailed such as condition file or step position which is related with specific

instruction statement in easy and quick way.

In a specific instruction statement, if you press [QuickOpen] key, the relating file

or detailed contents are displayed. When it ends after saving, press "Complete"[PF5],

when it ends without saving, press [Cancel].

T_P100

PF1 PF2 PF3 PF4 PF5

비상정지

14:39:38 *** M A N U A L *** A:0 S:H4

T=0

Robot:H6, 6axes, 4steps

S1 MOVE L, S=50%, A=0, H=0

S2 MOVE L, S=50%, A=0, H=0

WEAVON WEV#=1

ARCON ASF#=1

S3 MOVE L, S=40cm/min, A=0, H=0

ARCOF AEF#=1

WEAVOF

S4 MOVE L, S=50%, A=0, H=0

E ND

Select PF menu

>

Servie System Rel.WAIT Cond Set

ARC START CONDITION FILE

Cond No : [1]

Commnet : [Sample Welding]

Retry : <Ok,No>

Current : [200] A

Voltage : [ 20.0] V

Wait time : [0.10] sec

WCR Wait :<Disable,Enable>

POSE OF CURRENT STEP

X : [ 200.000] mm

Y : [1200.000] mm

Z : [ 240.000] mm

Rx : [-135.000] deg

Ry : [ 0.000] deg

Rz : [ 0.000] deg

Coordination:

.........

WEAVING CONDITION FILE

Cond No : [1]

Mode : <Single,Triangle,L>

Freq. : [2.5]Hz

Pattern Vertical : [2.0]mm

Horizontal: [2.0]mm

Angle : [90.0]deg

Forw Angle : [ 0.0]deg

CRATER CONDITION FILE

Cond No : [1]

Comment : [Sample Welding]

StickRecover: <Ok,No>

Current : [180] A

Voltage : [ 20.0] V

Crater time : [0.10] sec